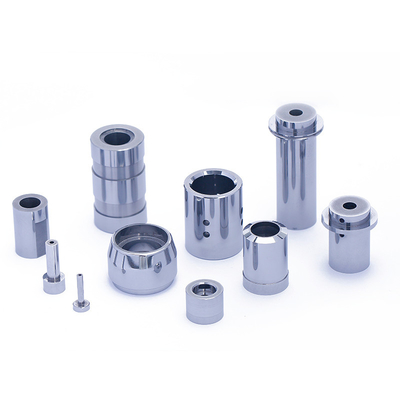

Carbide Coiling Needles for Lithium Battery Winding Machine High Precision Punch Mold Components

Application Field

Carbide winding needles are essential components in lithium battery production winding machines. With the rapid growth of electric vehicles, the demand for high-efficiency components like these has significantly increased, particularly for new energy lithium batteries.

Product Details

- Surface Treatment: Customized according to specifications

- Accuracy: Precision tailored to requirements (±0.001 mm capability)

- Material: Tungsten carbide needle body with HSS head for optimal cost-performance

- Customization: Fully customizable with CAD or 3D drawings required for non-standard orders

Material Properties

| Material |

Material Properties |

| Carbide |

Cemented carbide is a powder metallurgical composite offering exceptional hardness, wear resistance, and thermal stability. While more difficult to machine and costlier than die steel, its service life is significantly longer. |

| HSS |

High-speed steel provides superior abrasion resistance and toughness, ideal for small batch production or applications requiring high material toughness. |

Machining Technology

Our production capabilities include cylindrical grinding, internal circular grinding, optical profile grinding, flat grinding, thread machining, medium-speed wire cutting, low-speed wire cutting, and mirror discharge machining.

Why Choose Us

- Advanced Technology: Capable of forming complex shapes with high precision (±0.003 mm tolerance)

- Efficient Processing: Short production cycles with reliable delivery schedules

- Quality Assurance: Consistent high-quality output with rigorous quality control

- Confidentiality: Triple protection measures with optional NDA agreements

- Production Capacity: Multiple production lines with advanced equipment

- Cost-Effective: Competitive pricing through optimized design and material selection

With decades of specialization in tungsten carbide materials and molds, we combine research and development with high-end production equipment to deliver superior mold solutions offering excellent quality-price ratios.

Quality Criteria

- Wear Resistance

- Precision

- Corrosion Resistance

- Impact Strength

- Toughness

- Modulus of Elasticity and Rigidity

- Transverse Rupture Strength

FAQ

Q1: Do you produce special punch molds or punch die components?

A: Yes, we specialize in customized mold fabrication for various demanding applications and materials.

Q2: Do you accept low-volume sample orders? What's your MOQ for customization?

A: We accept sample orders (minimum 1 piece) with CAD/3D drawings required. Sample lead time is 10-15 days, negotiable for special requirements.

Q3: How do you ensure confidentiality?

A: We implement triple protection measures for all information and offer NDA agreements upon request.

Q4: What are your payment terms?

A: 30% deposit via T/T, with 70% balance due before delivery. Product photos provided before final payment.

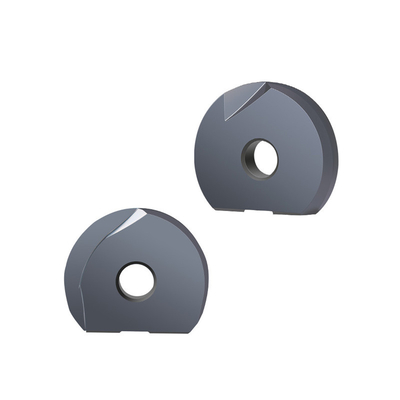

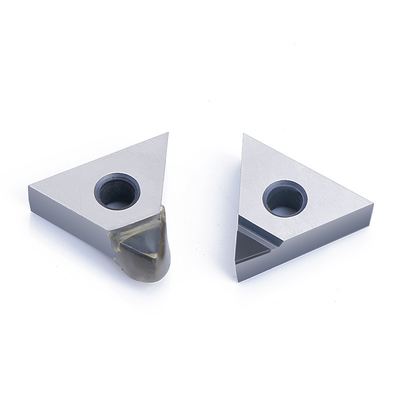

Q5: What products can you purchase from us?

A: We offer carbide inserts, end mills, drills, boring tools, cutting tools, and customized precision molds.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!