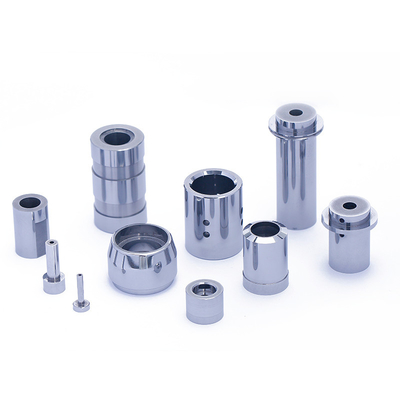

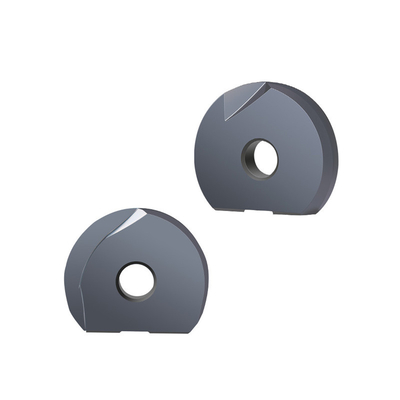

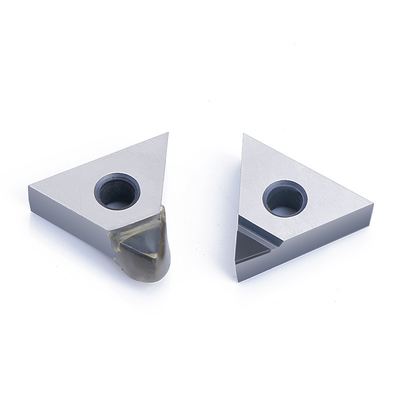

Customized High Precision Tungsten Carbide Punch Die/Mold For High Speed Stamping

Product Details---Mold&Die

Punch die&mold widely uses in high speed stamping application in auto parts industry. With our accurate tungsten carbide selection, higher tool life,higher customized and higher cost-effectiveness can be achieved.

What's more , the mechanical property of carbide can be altered by changing grain size and constitute to cope with wide range of tool performance demand. Through the deep research and development in material , we are able to modify the features of punch die in accordance with different machining methodology, and offer best-fit solutions for special work piece metals such as harden material with high wear resistance, Nicochrome which can withstand high temperature, and composite material with complicated mechanical properties.

Due to the customization, specific property depends on the material we use. But there are always relevant criteria for application we need to consider as below:

| Wear Resistance,Hardness |

| Comprehensive strength |

| Impact strength |

| Transverse rupture strength |

| Tribological properties |

| Specific weight |

| Magnetic properties |

| Modulus of elasticity,Rigidity |

| Thermal properties |

| Corrosion resistance |

| Oxidation Resistancet |

| Toughness |

Above standard will be requested in different application and demands! As for Punch die, you may concentrate more on wear resistance , impcat strength and transverse rupture strength etc. Welcome to contact us and start your customization!

Competitive Products Overview

Advantages

1. Competitive price: Based on accurate material selection, reasonable calculation and high-end equipments, our price is always competitive which can support customers at the first round of competition.

2. Stable quality : Entire and regorous quality inspection procedure, and experienced QCs inspect all the parts thoroughly which can ensure 100% high quality products sent to you!

3. On-time delivery: Although it depends on order Qty and index of process, usually we can ensure you the fastest delivery.

4.Made-to-order service available: except standard parts like in DIN, ISO, DAYTON, LANE, MISUMI, FIBRO, DME etc, also we can make special parts which depends on customers detailed requirements!

5.Comprehensive service: Comprehensive sales service are available over through before-sales, serviceing and sales-after. Pls feel free to contact us at anytime!

Advanced Machining Ability

Kinyet focuses on tungsten relevant material research and development all the time. Through constantly introducing new technology and increase investing on hign-end production equipment, Kinyet is able to offer molds solution with high-quality-price-ratio, include high precison,higher tooling life and cost effective etc. Now Kinyet is mergered with Drow. With this powerful combination, believe we will create more excellent products for consumer in the future!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!