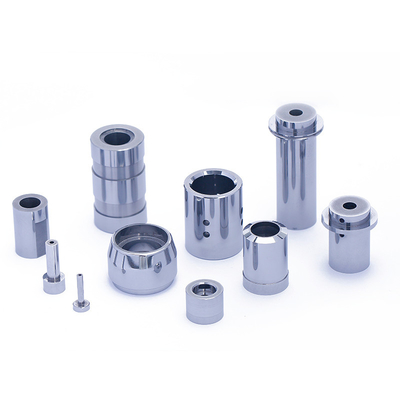

Solid Punch Mold Components Tungsten Carbide Rods For Stamping

Product Description

Solid Fine Grinding Tungsten Carbide Rods For Stamping and Carbide Cutting Tools

Ground Solid Tungsten Carbide Rods with fine grinding surface are mainly used for making milling cutter, drill, reamer and other tools in industrial applications. Through further processing, these fine grinding rods can become target cutting tools with stable performance. Pretreatment of surface and end face significantly reduces production machining time.

With decades of experience in Tungsten Carbide Material, we provide professional material selection advice and solutions for complex, fast-changing applications.

Product Details - Grinding Round Rods

| Accuracy |

D±0.001mm, L+0~+0.1 |

| Classification |

Stamping type fine grinding round rod, tool type fine grinding round rod (consult for more parameters) |

| Hardness |

89~94HRA (customizable per your requirements) |

| Inventory |

Some cutting tool rods in stock, others available for customization |

Involve Machining Technology

- Cylindrical grinding

- Internal circular grinding

- Optical profile grinding

- Flat grinding

- Thread machining

- Middle speed wire cutting

- Low speed wire cutting

- Mirror discharge machining

Why Choose Us

- Advanced Technology: Quickly form complex shapes and structures with precision

- Efficient Processing: Short production cycles and rapid delivery

- Product Quality: Consistent quality with high accuracy (±0.003mm)

- Confidentiality: Triple protection measures, NDA available

- High-end Equipment: Multiple production lines with advanced facilities

- Cost-effective: Competitive pricing through optimized design and material selection

Kinyet (now merged with Drow) focuses on tungsten material R&D, continuously introducing new technologies and investing in high-end equipment to deliver high-precision, long-life tooling solutions at competitive prices.

Quality Criteria

- Wear Resistance

- Precision

- Corrosion Resistance

- Impact Strength

- Toughness

- Modulus of Elasticity/Rigidity

- Transverse Rupture Strength

FAQ

Q1: Do you produce special punch mould or punch die components?

Yes, we specialize in customized mold fabrication, translating complex punch die concepts into reality. Our punch mold components are designed for demanding applications across various materials.

Q2: Do you accept low volume for sample order? What's your MOQ for customization?

Yes, we accept sample orders with MOQ of one piece. Please provide CAD/3D drawings with your inquiry. Sample lead time is 10-15 days (negotiable for special requirements).

Q3: Can we get confidentiality if we want to cooperate with you?

Absolutely. All company information, drawings, and PO details remain confidential. We can sign an NDA (Non-Disclosure Agreement) upon request.

Q4: What are your payment terms?

30% deposit via T/T, with 70% balance paid before delivery. We provide product and packaging photos before final payment.

Q5: What products can you buy from us?

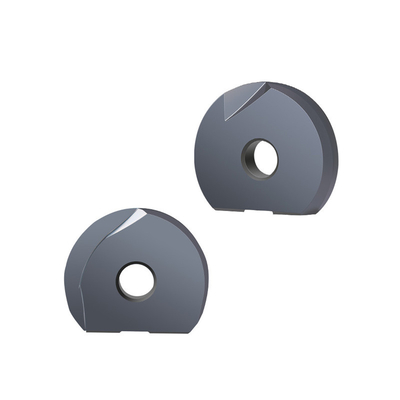

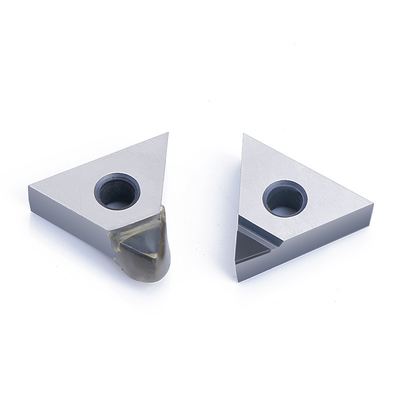

Carbide inserts, carbide end mills, carbide drills, carbide boring tools, cutting tools, and customized carbide precision molds.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!