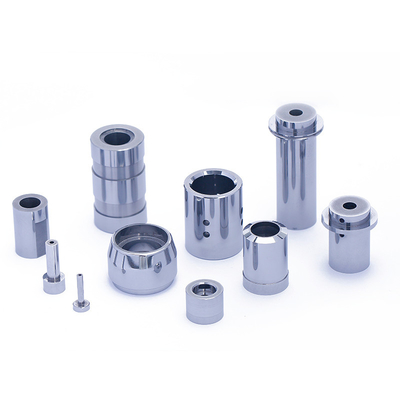

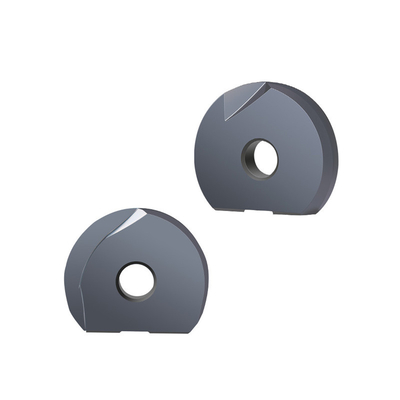

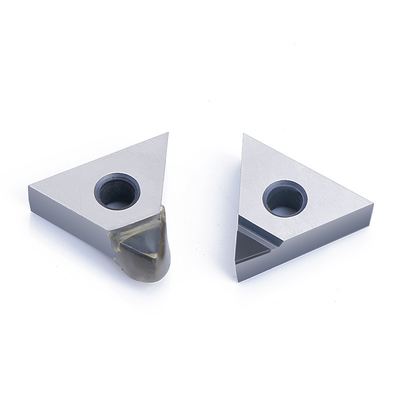

Punch Mold Components High Precision Carbide Optical Molds for Glass Lens Machining

Application Field

To meet customer demands for harsh environments, such as high temperature and high pressure during the pressing of glass lenses, Kinyet has developed a new series of optical-grade molds. These molds are designed to prevent oxidation and fogging during the customer's processing. Additionally, we offer a complete set of high-precision molds with tool fitting clearance.

Product Details — Optical Molds

- Surface Roughness: RZ ~ 0.2 µm / F1.0 mm/min

- Accuracy: ±0.001 mm

- Customization: Fully customizable. There is no standard stock for this series; only non-standard orders are accepted. Please attach CAD or 3D drawings to your inquiry. Thank you.

- Suitable Material: Optical-grade series, including tungsten carbide and ceramics, with the following properties:

| Material |

Material Properties |

| Carbide |

Cemented carbide is a powder metallurgical composite made up of one or more hard material phases (e.g., tungsten carbide) and a binding material (e.g., cobalt). It is extremely hard, characterized by high wear resistance and thermal stability, making it suitable for various applications that require wear-resistant tools or components. Although machining carbide is more challenging and costly compared to die steel, its service life is often several times longer. |

| Ceramic |

Ceramic materials demonstrate excellent high-temperature resistance, playing a crucial role in applications with continuous operating temperatures ranging from 180 °C to over 1200 °C. Compared to metallic materials, oxide ceramics are particularly resistant to chemical attack, especially in acidic and alkaline environments. Common types include alumina, zirconia, silicon carbide, and silicon nitride ceramics. |

Involve Machining Technology:

- Involve Production Technology: Cylindrical grinding, internal circular grinding, optical profile grinding, flat grinding, thread machining, middle speed wire cutting, low speed wire cutting, mirror discharge machining and so on.

Why Choose Us

- Advanced Technology: We can quickly form complex shapes and various structures while maintaining precision.

- Efficient Processing: Our short production cycles and rapid delivery ensure that shipments adhere to delivery schedules.

- Product Quality: We guarantee consistent quality with high accuracy, achieving tolerances of up to ±0.003 mm.

- Confidentiality System: We implement triple confidentiality measures to protect your information. If needed, we can sign a Non-Disclosure Agreement (NDA) for added assurance.

- High-End Equipment: Our outstanding processing capacity is supported by multiple production lines, advanced equipment, and professional facilities.

- Cost-Effective Solutions: Our reasonable designs and material selections enable us to offer competitive prices, helping you secure more favorable pricing for comparable products.

Kinyet is committed to continuous research and development of tungsten-related materials. By regularly introducing new technologies and investing in high-end production equipment, we provide mold solutions with an excellent quality-to-price ratio, including high precision, longer tooling life, and cost-effectiveness. With our recent merger with Drow, we are poised to create even more exceptional products for consumers in the future!

Quality Criteria

- Wear Resistance

- Precision

- Corrosion Resistance

- Impact Strength

- Toughness

- Modulus of Elasticity and Rigidity

- Transverse Rupture Strength

FAQ

Q1: Do you produce special punch molds or punch die components?

A: Yes, we specialize in customized mold fabrication and can translate complex punch die ideas into reality. Our punch mold components are designed and tailored for various demanding applications and materials.

Q2: Do you accept low volume sample orders? What’s your MOQ for customization?

A: Yes, we accept sample orders with a minimum order quantity (MOQ) of one piece. Please attach CAD or 3D drawings to your inquiry. The sample lead time is 10 to 15 days, which can be negotiated for special requirements.

Q3: Can we ensure confidentiality if we cooperate with you?

A: Absolutely. All your information, including company details, drawings, and purchase orders, will be kept confidential. We can sign an NDA if you require one.

Q4: What are your payment terms?

A: Our payment terms are T/T: 30% as a deposit and 70% balance before delivery. We will provide photos of the products and packaging for your approval before you pay the balance.

Q5: What products can you supply?

A: We offer carbide inserts, carbide end mills, carbide drills, carbide boring tools, cutting tools, and customized carbide precision molds.

Q6: Can you send products to our forwarder in China?

A: Yes, if you have a forwarder in China, we would be glad to send products to them.

Q7: What about packaging?

A: We use plastic boxes for packaging, with shockproof filling materials transported in cartons. Custom packaging options are available based on product shapes.

Q8: Does your company accept customization?

A: Yes, we offer OEM and ODM services, supported by our dedicated professional R&D team.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!