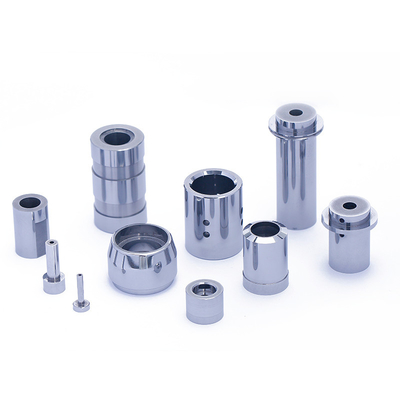

Fastening Dies Punch Pin And Nozzle Customized Polished Punch Mold Components Precision Mold Components

Product Description:

The Fastening Die is widely utilized for cold heading and cold punching of standard parts, including bearings, screws, and nuts. DORW's skilled team boasts over a decade of experience in the fastening industry, possessing in-depth knowledge of tungsten carbide properties. They offer comprehensive solutions primarily focused on high-end fastener mold production.

Features:

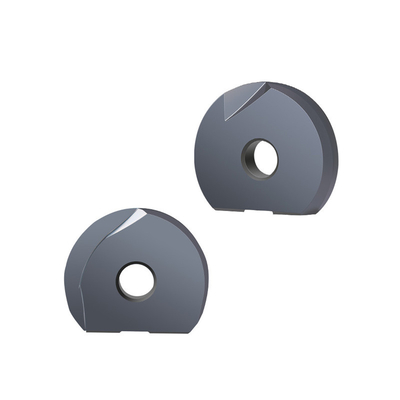

Carbide

Cemented carbide is a powder metallurgical composite composed of one or more hard material phases (e.g., tungsten carbide) and a binding material (e.g., cobalt). It is an exceptionally hard material, characterized by high wear resistance and thermal stability. This makes it ideal for various applications that require tools or components with outstanding wear resistance. Although cemented carbide is more challenging to machine and has a higher material cost compared to die steel, its service life is often several times longer.

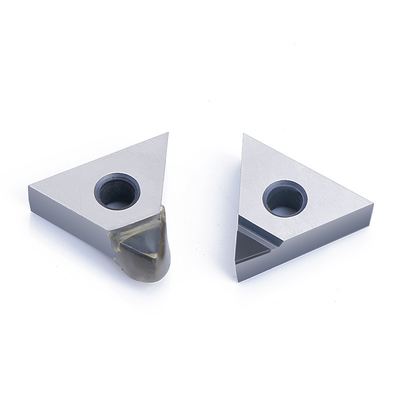

Ceramic

Ceramic materials exhibit excellent high-temperature resistance, making them crucial for applications operating within a continuous temperature range of 180 °C to over 1200 °C. Oxide ceramics, in particular, are noted for their resistance to chemical attack, especially in acidic and alkaline solutions. Common types include alumina, zirconia, silicon carbide, and silicon nitride ceramics.

High-Speed Steel

High-speed steel offers superior abrasion resistance and toughness, making it suitable for general use. It is primarily employed in small batch production or in applications where high material toughness is essential.

Technical Parameters:

Incorporating advanced production technology is essential to meet our customers' needs. We offer a comprehensive range of services, including cylindrical grinding, internal circular grinding, optical profile grinding, flat grinding, thread machining, medium-speed wire cutting, low-speed wire cutting, and mirror discharge machining.

Our cutting-edge technologies ensure that our machinery is reliable for all types of production and machining requirements. With our state-of-the-art equipment, customers can be confident in receiving products that fully meet their specifications.

Applications:

Punch Mold Components by Drow

Drow's Punch Mold components, model number Punch Mold, are proudly manufactured in China and certified with ISO 9001. They are available with a minimum order quantity of just 1 set, and pricing is negotiable. The product is packaged in either a plastic box or plastic film, with a delivery time of 7-14 days. Payment terms require 100% T/T before shipment, and the supply capability is contingent upon the provided drawings.

The processing technologies employed for Drow's Punch Mold components include cylindrical grinding, internal circular grinding, optical profile grinding, flat grinding, thread machining, middle-speed wire cutting, low-speed wire cutting, mirror discharge machining, and more. We also offer OEM/ODM services with a minimum order quantity of 1 set. The components are manufactured from high-quality materials, such as tungsten carbide or HSS, and are packaged in cartons.

Drow's Punch Mold Components are the ideal choice for punching mold applications, combining a reputable brand, certification, advanced processing technology, premium materials, and comprehensive packaging and OEM/ODM services.

Customization:

| Brand Name: |

Drow |

| Model Number: |

Punch Mold |

| Place of Origin: |

China |

| Certification: |

ISO9001 |

| Minimum Order Quantity: |

1 set |

| Price: |

Negotiable |

| Packaging Details: |

Plastic box or Plastic film |

| Delivery Time: |

7–14 days |

| Payment Terms: |

100% T/T before shipping |

| Supply Ability: |

Depends on the drawing |

| Service: |

OEM/ODM |

| Shape: |

Customized |

| Material: |

Tungsten Carbide or HSS |

| Application: |

Punch Machine |

| Size: |

Customized |

We offer a range of customized services for our Mold Punching Components. Our professional team is experienced in designing and producing high-quality components tailored to your specific requirements. Made from superior-grade tungsten carbide or HSS, our Mold Punching Components can be customized to fit your application. We provide a wide variety of sizes and shapes to meet your needs. With our competitive pricing and exceptional service, our Mold Punching Components are sure to exceed your expectations.

Support and Services:

Punch Mold Components Technical Support and Services

We offer comprehensive technical support and services to ensure the optimal performance of your Punch Mold Components. Our services include:

- Assistance with product selection and application

- Regular maintenance and repairs

- Technical advice and troubleshooting

We are dedicated to providing our customers with professional and efficient service. Our team of experienced engineers and technicians is available to assist you with any issues you may encounter.

If you need assistance with your Punch Mold Components, please feel free to contact us.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!