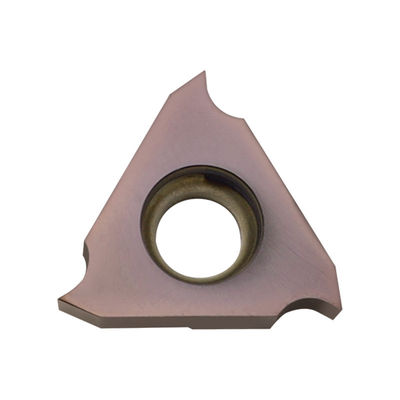

Wear Resistance CNC Grooving Inserts TGF32 GTMH32-SSH SS LS-100 For CNC Lathe

Product Description

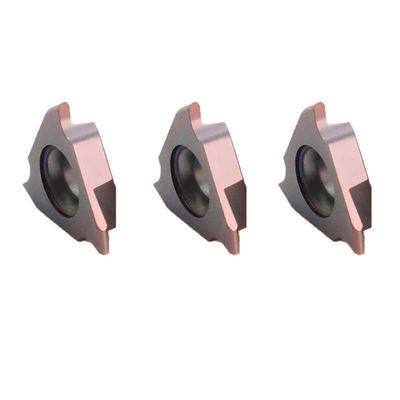

TGF32 GTMH32-SSH/SS/LS-100R Wear Resistance Carbide Grooving Inserts For CNC Lathe

Application Field

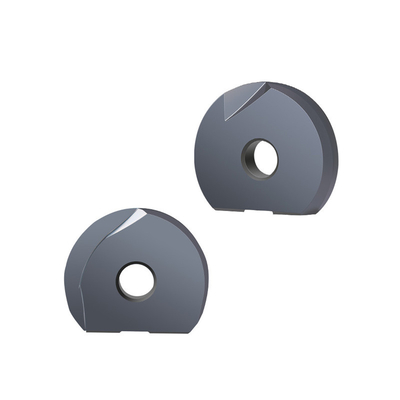

GTMH32-SSH/SS/LS is a series of carbide grooving inserts, mainly used for turning & grooving operations on lathe & CNC machines which are available in different shapes & cutting angles.

Inserts Production Standard

The insert size details can be processed separately according to customer requirements, and refer to the standard: Kyocera TGF32 series, NTK's GTM32, GTMX32, GTMH32 series, etc.

TGF32: Kyocera TGF32 series, a popular series of carbide inserts. Our standard production size and standing stock specifications mainly refer to this series.

GTMH32: A popular series of carbide insert, named by NTK. Similar specification as TGF32. "SSH/SS/LS" represents one of sub-series. "100R" represents the specification and cutting orientation of insert.

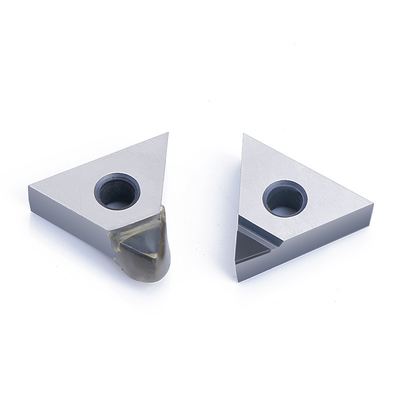

Product Details - GTMH32-SSH,SS,LS-100R

- Excellent material: 100% original carbide powder for excellent wear resistance and toughness.

- Dimensions: ①CW:0.33~2.50mm ②CDX: 0.8~2.50mm ③RE: 0.05~0.10mm

- Advanced coating: Customized per application with corrosion and wear resistance technology.

- Fine grinding process: High smoothness surface with good cutting edge quality and minimal friction.

- Perfect fit: Accurate edge strips prevent micro-vibration during processing.

- Applicable materials: Uncoated for aluminum/non-ferrous; Coated for steel, alloy, mold steel, ductile iron.

- Customization: Available for non-standard requirements with CAD/3D drawings.

- Mature production: Manufactured using high-end EU processing equipment.

Product Features

- Chamfering and tip-arc processing protects insert edge and ensures smooth workpiece surface.

- High performance composite coating provides super hard and smooth surface.

- Professional chip-breaker design for perfect cutting performance.

- Precise dimensions prevent micro-vibration during processing.

- European base material for better oxidation and wear resistance.

- Customized designs available for dimensions, coating, chip-breaker, and material grade.

Product Specification

| Part Number |

Dimensions(mm) |

Applicable Tool Holders |

| TGF32 R/L |

CW: 0.33

CDX: 0.8

RE: 0.05 |

KTGF R/L S...KTGF R/L GTT R/L NGT... R/L |

CW: 0.50

CDX: 1.2

RE: 0.05 |

CW: 0.75

CDX: 2.0

RE: 0.1 |

| CW: 0.95 |

| CW: 1.00 |

| CW: 1.20 |

| CW: 1.25 |

| CW: 1.40 |

| CW: 1.45 |

| CW: 1.50 |

| CW: 1.75 |

CW: 2.00

CDX: 2.5 |

| |

CW: 2.50 |

|

The above are our standard production size and standard stock specifications. Size details can be customized per customer requirements.

Entire Production Quick View

- Use 100% original carbide powder to sinter insert blank

- Flat grinding machining

- Surrounding grinding machining

- Create insert cutting edge

- Chamfering and tip-arc processing

- Composite Coating

Quality Inspection

Why Choose Us

- Technical innovation: Complex surfaces and functional structures can be quickly formed and kept accurate.

- Processing speed: Short production cycle with fast delivery time.

- Product quality: High precision up to 0.005-0.001mm.

- Confidentiality system: Triple protection measures.

- Fully equipped: Multiple production lines with advanced equipment.

- Cost-effective: Competitive pricing for same level products.

FAQ

Q1: Do you produce special cutting inserts or tools?

A: Yes, we specialize in customized cutter fabrication for various demanding applications and materials.

Q2: Do you accept low volume for sample order? What's your MOQ for special tools?

A: Sample order MOQ is one piece with 2-3 days lead time. Special requirements can be negotiated.

Q3: If we want to cooperate with you, is it possible to get confidentiality?

A: All information will be kept confidential. We can sign NDA (non disclosure agreement).

Q4: What is your terms of payment?

A: T/T 30% deposit, 70% balance before delivery with product photos provided.

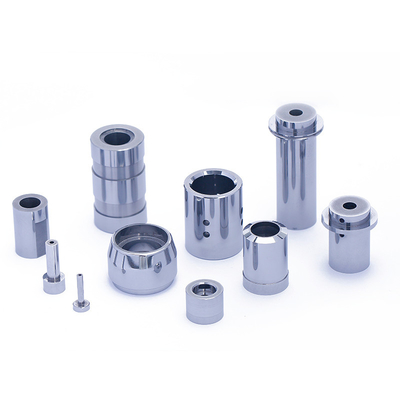

Q5: What can you buy from us?

A: Carbide inserts, end mills, drills, boring tools, cutting tools & customized carbide precision molds.

Q6: Do you test all your goods before delivery?

A: Yes, 100% testing before delivery with ISO9001 production and rigorous quality control.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!