TGF32 GTMH32GX-050R Carbide Grooving Inserts for CNC Lathe

Application Field

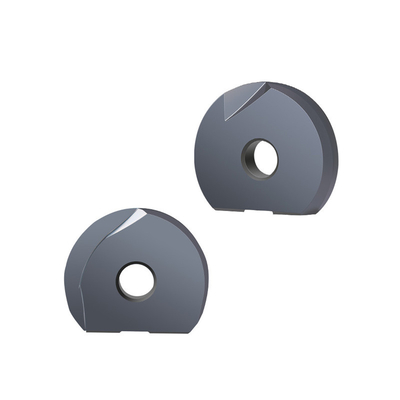

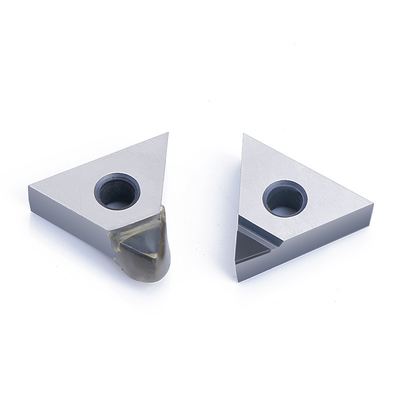

The GTMH32-GX series of carbide grooving inserts are designed for turning and grooving operations on lathe and CNC machines, available in various shapes and cutting angles.

Production Standard

Insert sizes can be customized to customer requirements, adhering to standards including:

- TGF32: Kyocera TGF32 series - our standard production reference

- GTMH32: NTK's series with similar specifications to TGF32

- "GX" denotes a sub-series, while "050R" indicates specification and cutting orientation

Product Details - GTMH32-GX

- Material: 100% original carbide powder for superior wear resistance and toughness

- Dimensions: CW: 0.33-2.50mm | CDX: 0.8-2.50mm | RE: 0.05-0.10mm

- Coating: Advanced coating technology for corrosion and wear resistance

- Grinding: High smoothness surface with quality cutting edges to reduce friction

- Fit: Precise edge strips minimize vibration during operation

- Materials: Uncoated for aluminum/non-ferrous metals; Coated for steel/iron

- Customization: Available for non-standard requirements with CAD/3D drawings

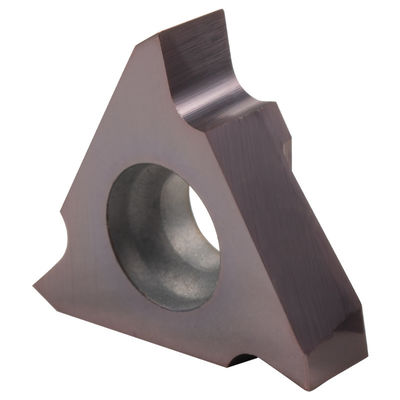

Product Features

- Chamfered cutting edge with tip-arc processing for edge protection

- High-performance composite coating for hard, smooth surfaces

- Efficient chip-breaker design for optimal cutting performance

- Precise dimensions ensure perfect fit with tool holders

- European-sourced base material for oxidation and wear resistance

- Custom designs available for dimensions, coating, and chip-breaker

Product Specification

| Part Number |

CW (mm) |

CDX (mm) |

RE (mm) |

Applicable Tool Holders |

| TGF32 R/L |

0.33-2.50 |

0.8-2.5 |

0.05-0.10 |

KTGF R/L S...KTGF R/L GTT R/L NGT... R/L |

Note: Standard sizes shown; custom dimensions available per customer requirements.

Production Process

- Sintering with 100% original carbide powder

- Flat grinding machining

- Surrounding grinding machining

- Cutting edge creation

- Edge chamfering and tip-arc processing

- Composite coating application

Quality Inspection

Why Choose Our Products

- Technical innovation for complex surface accuracy

- Fast processing and reliable delivery times

- High precision (0.005-0.001mm tolerance)

- Strict confidentiality measures including NDA options

- Advanced production facilities with multiple lines

- Competitive pricing for superior quality

Frequently Asked Questions

Q1: Is confidentiality guaranteed for our cooperation?

A: Yes, all information including company details and drawings remain confidential. We can sign an NDA if required.

Q2: What are your payment terms?

A: 30% deposit via T/T, with 70% balance paid before delivery after product photos are approved.

Q3: How is product quality assured?

A: 100% inspection for first batches, with raw material testing and production checks before shipping.

Q4: What other products do you offer?

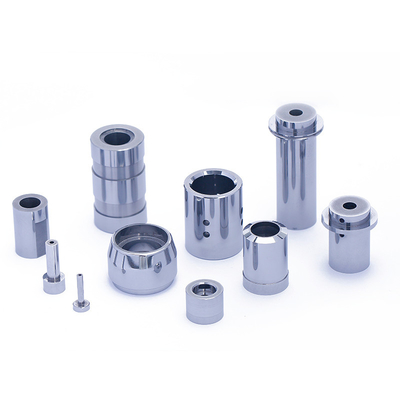

A: We provide carbide inserts, end mills, drills, boring tools, and custom precision molds.

Q5: Are volume discounts available?

A: Yes, we offer competitive pricing and discounts for large quantity orders.

Q6: Do you accept small sample orders?

A: Yes, sample MOQ is one piece with 2-3 day lead time for standard items.

Q7: What packaging is used?

A: Standard packaging includes shockproof plastic boxes in cartons, with custom options available.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!