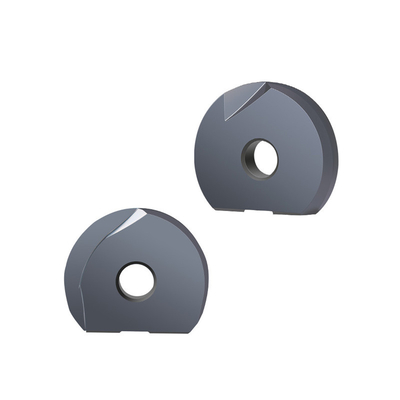

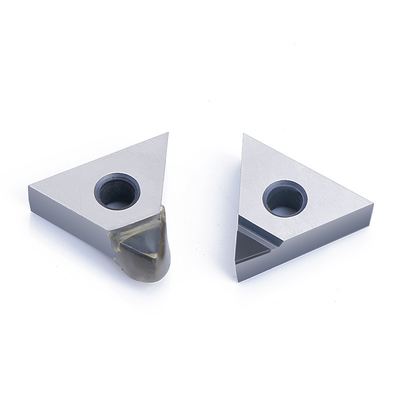

TGF32 GTMH32-R-050R-E025 Carbide Grooving Inserts Wear Resistance For CNC Lathe

Application Field

GTMH32-R series carbide grooving inserts are designed for turning and grooving operations on lathe and CNC machines. Available in various shapes and cutting angles, these inserts require careful selection of geometry, grade, shape, size, nose radius, and lead angle for optimal chip control and machining performance.

Inserts Production Standard

Custom sizing available according to customer requirements, adhering to industry standards including:

- TGF32: Kyocera TGF32 series - our standard production reference

- GTMH32: NTK's popular series (R sub-series), with "050R-E025" indicating specification and cutting orientation

Product Details - GTMH32-R-050R-E025

- Material: Premium tungsten carbide powder for superior wear resistance and toughness

- Dimensions: CW: 0.33-2.50mm | CDX: 0.8-2.50mm | RE: 0.05-0.10mm

- Coating: Advanced coating technology for corrosion and wear resistance

- Surface Finish: Fine grinding process ensures high smoothness and quality cutting edges

- Precision Fit: Accurate edge strips minimize micro-vibration during operation

- Material Compatibility: Uncoated for aluminum/non-ferrous; Coated for steel, alloy, and iron

- Customization: Available upon request with CAD/3D drawings

Product Features

- Chamfered cutting edges with tip-arc processing for edge protection

- High-performance composite coating for hard, smooth surfaces

- Professional chip-breaker design for optimal cutting performance

- Precision dimensions ensure perfect holder fit and vibration reduction

- European-sourced base material for superior oxidation resistance

- Custom options available for dimensions, coating, and chip-breaker design

Product Specification

| Part Number |

Dimensions (mm) |

Applicable Tool Holders |

| TGF32 R/L |

CW: 0.33 | CDX: 0.8 | RE: 0.05 |

KTGF R/L S...KTGF R/L GTT R/L NGT... R/L |

| CW: 0.50 | CDX: 1.2 | RE: 0.05 |

| CW: 0.75 | CDX: 2.0 | RE: 0.1 |

| CW: 0.95 |

| CW: 1.00 |

| CW: 1.20 |

| CW: 1.25 |

| CW: 1.40 |

| CW: 1.45 |

| CW: 1.50 |

| CW: 1.75 |

| CW: 2.00 | CDX: 2.5 | RE: 0.1 |

| CW: 2.50 |

|

Note: Standard sizes shown; custom dimensions available per customer requirements.

Production Process

- Sintering of original carbide powder to form blank

- Flat surface grinding

- Surrounding surface grinding

- Cutting edge creation per specifications

- Edge chamfering and tip-arc processing

- Composite coating application

Quality Assurance

Our Advantages

- Advanced EU processing equipment

- Rapid production cycles

- High precision (0.005-0.001mm tolerance)

- Strict confidentiality protocols

- Full production capabilities

- Competitive pricing

Frequently Asked Questions

Q1: What is your terms of payment?

A: 30% deposit via T/T, with 70% balance before delivery. Product photos provided prior to final payment.

Q2: How can we trust your product quality?

A: 100% inspection for first batch, random checks thereafter. Material testing before production and final verification before shipping.

Q3: How do you maintain long-term relationships?

A: Through consistent quality, competitive pricing, and treating every customer as a valued partner.

Q4: Are you a factory or trading company?

A: We are a professional manufacturer with decades of experience in precision hardware tools.

Q5: Who are we?

A: Established in 2010 in Guangdong, China, serving global markets with 51-100 employees.

Q6: Do you accept customization?

A: Yes, OEM and ODM services available with dedicated R&D support.

Q7: What's your delivery method?

A: Customized shipping solutions based on customer requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!