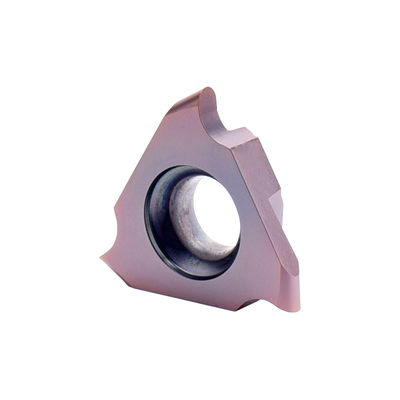

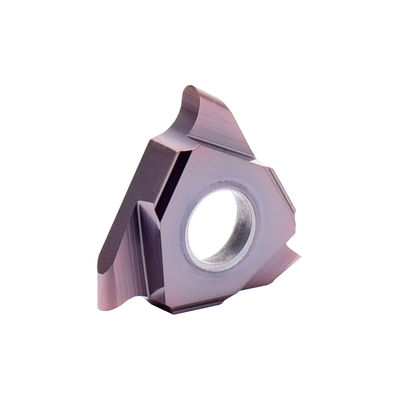

TGF32L 150 010 Carbide Grooving Inserts High Hardness For CNC Machine Holder

Product Overview

TGF32L 150 010 High Hardness Carbide Grooving Inserts for CNC Machine Holder

Application Field

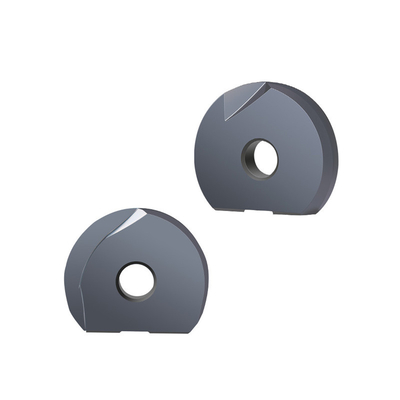

TGF32 is a series of carbide grooving inserts, primarily used for turning & grooving operations on lathe & CNC machines, available in different shapes & cutting angles.

Production Standard

Insert size details can be customized according to customer requirements, referencing standards including:

- Kyocera TGF32 series - "L150 010" represents the specification and cutting orientation

- NTK's GTM32, GTMX32, GTMH32 series - Similar specifications to TGF32

Product Details

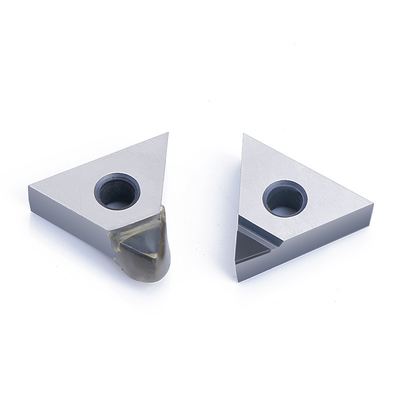

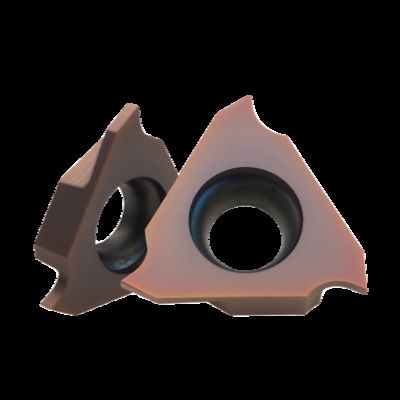

- Material: 100% original carbide powder for excellent wear resistance and toughness

- Dimensions: CW: 0.33-2.50mm | CDX: 0.8-2.50mm | RE: 0.05-0.10mm

- Coating: Advanced coating technology for corrosion and wear resistance

- Grinding Process: High smoothness surface with quality cutting edges to reduce friction

- Precision Fit: Accurate edge strips minimize micro-vibration during processing

- Material Compatibility: Uncoated for aluminum/non-ferrous; Coated for steel, iron, etc.

- Customization: Available for non-standard requirements with CAD/3D drawings

Product Features

- Chamfered cutting edge with tip-arc processing for edge protection

- High-performance composite coating for hard, smooth surface

- Efficient chip-breaker design for optimal cutting performance

- Precise dimensions for perfect fit with tool holders

- European-sourced base material for oxidation and wear resistance

- Custom designs available for dimensions, coating, and chip-breaker

Product Specifications

| Part Number |

Dimensions (mm) |

Applicable Tool Holders |

| TGF32 R/L 033-005 |

0.33 | 0.8 | 0.05 |

KTGF R/L S...KTGF R/L GTT R/L NGT... R/L |

| TGF32 R/L 050-005 |

0.50 | 1.2 | 0.05 |

| TGF32 R/L 075-010 |

0.75 | 2.0 | 0.1 |

| TGF32 R/L 095-010 |

0.95 |

| TGF32 R/L 100-010 |

1.00 |

| TGF32 R/L 120-010 |

1.20 |

| TGF32 R/L 125-010 |

1.25 |

| TGF32 R/L 140-010 |

1.40 |

| TGF32 R/L 145-010 |

1.45 |

| TGF32 R/L 150-010 |

1.50 |

| TGF32 R/L 175-010 |

1.75 |

| TGF32 R/L 200-010 |

2.00 | 2.5 |

| TGF32 R/L 250-010 |

2.50 |

|

Note: Standard sizes shown; custom dimensions available per customer requirements.

Production Process

- 100% original carbide powder sintering

- Flat grinding machining

- Surrounding grinding machining

- Cutting edge creation

- Chamfering and tip-arc processing

- Composite coating application

Quality Assurance

Key Advantages

- Stable performance with excellent impact resistance

- Extended tool lifetime

- Negative chamfer design for blade strength

- Smooth cutting performance

Frequently Asked Questions

Q1: What else can you buy from us?

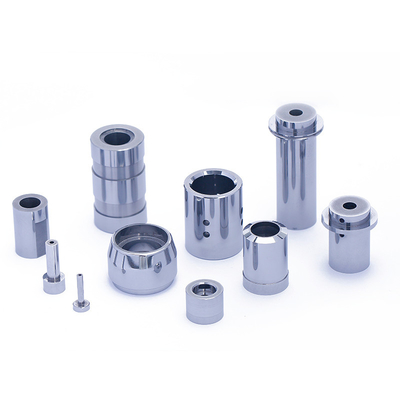

A: Carbide inserts, carbide end mills, carbide drills, carbide boring tools, cutting tools & customized carbide precision molds.

Q2: Can we get a discount for large quantity orders?

A: Yes. For substantial order quantities, we offer our best pricing with applicable discounts.

Q3: Do you offer OEM and ODM services?

A: Yes. With over 10 years of OEM experience, our R&D team can design products to meet your specific requirements.

Q4: Do you accept small sample orders? What's your MOQ?

A: Yes, we accept sample orders with MOQ of one piece. Sample lead time is typically 2-3 days.

Q5: How do you maintain long-term business relationships?

A: We ensure consistent quality and competitive pricing while treating every customer with respect and sincerity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!