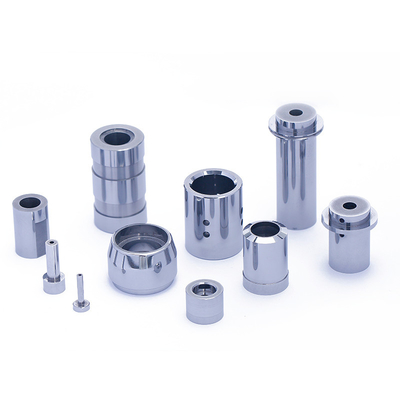

Carbide Boring Tools with SIM Locking Precision Holder and Internal Coolant Design for Improved Tool Lifespan

Introducing our reliable tool holder and tool bar designed specifically for inner hole boring tools, featuring an innovative internal water coolant system to enhance tool lifespan. The locking pin design of the tool handle ensures efficient and repeatable clamping, significantly reducing labor time and costs.

Our exceptional R&D team, combined with standardized factory production, allows us to meet your specific requirements. We welcome you to contact us for more information!

Product Details---SIM Locking Precision Holder

- Material: Steel

- Usage: Tool holder for boring tools and mini lathes. Compatible with CNC lathes, centering machines, cutter arranging machines, skateboard lathes, turret lathes, and other longitudinal lathes.

- Color: Black coating

- Small-end Diameter: 4.0–7.0 mm

- Item Weight: 0.20 kg per piece

- Internal Coolant Design: Features a central outlet water coolant design to enhance tool lifespan.

Specific product information as below:

| Brand Name: |

Drow |

| Model Number: |

SIM boring tool-holders |

| Customized support: |

OEM, ODM |

| Product type: |

Locking precision Toolholders |

| Material: |

Steel |

| Color: |

Black coating |

| Small-end Diameter |

4.0mm-7.0mm |

| Weight of item: |

0.20kg/pcs |

| Characteristic: |

Internal coolant design |

| Usage: |

Tool holder of boring tools,

internal Turning Tool, CNC Machining |

| Compatible machine: |

CNC lathes, centering machines, cutter arranging machine skateboard lathes, turret lathes and other longitudinal lathes |

| Mainly suitable for machine tool brands |

Swiss TORNOS lathe, Citizen, Nomura, Tsugami,Star,Miyano,etc |

| Machining type |

Boring and Turning |

| Customization |

Professional and Available |

Product Features:

-

Taiwan Seiko: Engineered for anti-shake and anti-vibration performance.

-

Robust Stability: Anti-seismic and anti-bending features ensure stable operation, enhancing production quality and efficiency.

-

Central Coolant Outlet: Innovative internal coolant design for optimal tool lifespan.

-

Premium Materials: Precision-ground high-quality tool steel, subjected to high-temperature quenching for superior toughness.

-

Efficient Clamping: The locking pin design of the tool handle facilitates efficient and repeatable clamping, significantly reducing labor time costs.

Why choose us:

-

Innovation in Production Technology: Capable of rapidly forming complex surfaces and functional structures while maintaining high precision.

-

Processing Speed: Short production cycles and fast delivery times ensure timely fulfillment of orders.

-

Strict Quality Control: Rigorous quality management practices maintain consistent product quality.

-

Confidentiality System: Triple-layer confidentiality measures provide enhanced protection and assurance for your projects.

-

Comprehensive Equipment: Robust processing capabilities, multiple production lines, advanced machinery, and complete supporting facilities.

-

Competitive Pricing: Thoughtful design and material selection allow us to offer competitive prices, ensuring better value for you.

Product Specification

| Model |

D |

D1 |

L |

h |

Clamping Screw |

| SIM0012-D4 |

12 |

4.0 |

75 |

11 |

T0507 |

| SIM0012-D5 |

12 |

5.0 |

75 |

11 |

T0507 |

| SIM0012-D6 |

12 |

6.0 |

75 |

11 |

T0507 |

| SIM0016-D4 |

16 |

4.0 |

75 |

14 |

_T0507 |

| SIM0016-D5 |

16 |

5.0 |

75 |

14 |

T0507 |

| SIM0016-D6 |

16 |

6.0 |

75 |

14 |

T0507 |

| SIM0016-D7 |

16 |

7.0 |

75 |

14 |

T0507 |

| SIM0020-D4 |

20 |

4.0 |

90 |

18 |

T0507 |

| SIM0020-D5 |

20 |

5.0 |

90 |

18 |

T0507 |

| SIM0020-D6 |

20 |

6.0 |

90 |

18 |

T0507 |

| SIM0020-D7 |

20 |

7.0 |

90 |

18 |

T0507 |

| SIM0022-D4 |

22 |

4.0 |

90 |

20 |

T0507 |

| SIM0O22-D5 |

22 |

5.0 |

90 |

20 |

T0507 |

| SIM0022-D6 |

22 |

6.0 |

90 |

20 |

T0507 |

| SIM0022-D7 |

22 |

70 |

90 |

20 |

T0507 |

| SM0025-D4 |

25 |

4.0 |

90 |

23 |

T0507 |

| SIM0025-D5 |

25 |

5.0 |

90 |

23 |

T0507 |

| SIM0025-D6 |

25 |

6.0 |

90 |

23 |

T0507 |

| SIM0025-D7 |

25 |

7.0 |

90 |

23 |

T0507 |

| SIM1000-D4 |

25,4 |

4.0 |

90 |

23.4 |

T0507 |

| SIM1000-D5 |

25.4 |

5.0 |

90 |

23.4 |

T0507 |

| SIM1000-D6 |

25.4 |

6.0 |

90 |

23.4 |

T0507 |

| SIM1000-D7 |

25.4 |

7.0 |

90 |

23.4 |

T0507 |

| Model |

D |

D1 |

L |

L1 |

L2 |

dp Water hole pipe |

Clamping Screw |

| SIM22S-D4 |

22 |

4.0 |

52 |

30 |

25 |

6.0 |

T0507 |

| SIM22S-D5 |

22 |

5.0 |

52 |

30 |

25 |

6.0 |

T0507 |

| SIM22S-D6 |

22 |

6.0 |

52 |

30 |

25 |

6.0 |

T0507 |

| SIM22S-D7 |

22 |

7.0 |

52 |

30 |

25 |

6.0 |

T0507 |

Product Show

Rigorous Quality Inspection

1.Projector detection

2.ZOLLER detection

3.Swis edging

4.German forging difference process detection

5.Edge passivation detection

6.Coreless grinding

FAQ

Q1: How can we guarantee quality?

A: Always a pre-production sample before mass production;Always final Inspection before shipment;

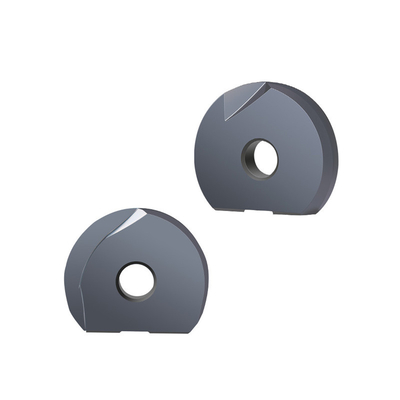

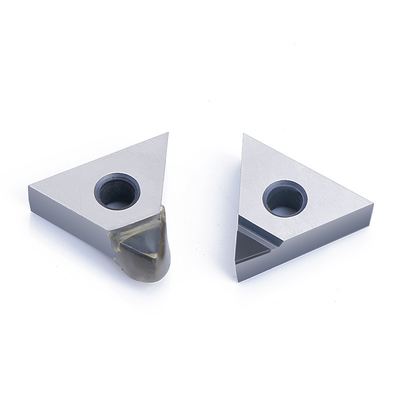

Q2: What can you buy from us?

A: Carbide insert,carbide end mill,carbide drill,carbide boring,cutting tools,tool holders&customized carbide precision molds

Q3:Why should you buy from us not from other suppliers?

A: We Drow devote ourselves in research and development of tungsten carbide, cutting tools, cutting inserts, and new materials, specializing in the design and production of carbide turning inserts , indexable inserts, CNC inserts etc.

Q4: What is your terms of payment?

A: T/T 30% as deposit, and 70% balance before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q5:Do you accept low volume for sample order? And what’s your MOQ for special tools?

A: Yes, we do. For sample order, MOQ one piece is accepted, and the sample lead time is 2-3 days. It can be negotiated for special requirement.

Q6: What about the package?

A: We use plastic boxes to pack our products, and filled plastic is shockproof and transported in cartons. also It can make as you need and depend on the shapes of the product.

Q7:Is your company accept customization?

A: OEM and ODM are available. And we have our own professional R&D team servicing for you.

Q8: How do you keep long-term and good relationship with our business?

A:1. Consistent quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend. We sincerely do business and make friends with them, no matter where they come from.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!