Locking Precise MBQR Profiling Tool for Internal Hole Finishing in Mini Turning Lathe

Drow_Carbide_Boring_Tools_EN.pdf

Drow_Carbide_Boring_Tools_MD_EN.pdf

Application Field:

The MBQR is an internal boring and profiling tool widely utilized for finishing inner hole profiling in mini turning lathes. It is particularly well-suited for machine tools such as CNC lathes and centering machines.

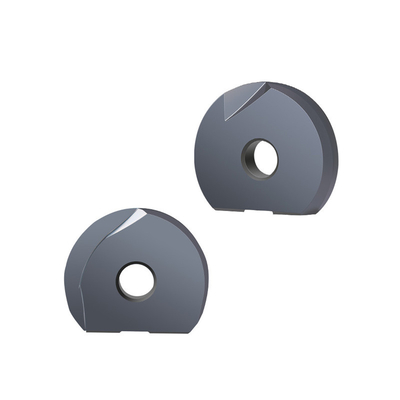

Unlike the round shank MPR, the MBQR features a rear-end tilt design, making it compatible with precision tool holders. Additionally, its advanced nanometer coating on ultrafine carbide enhances both the smoothness of the machining surface and its wear resistance.

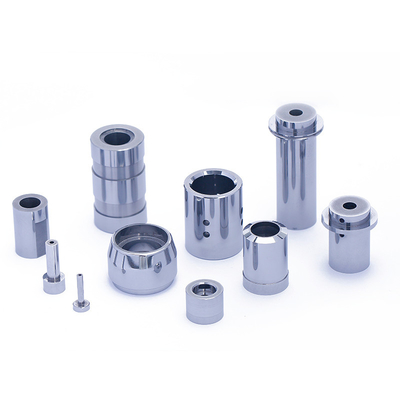

Product Details--- MBQR Profiling Tool

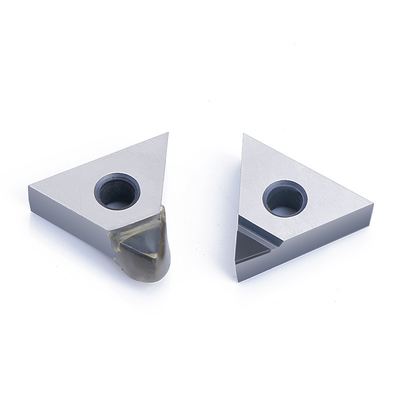

- Tool Material: 100% virgin tungsten carbide.

- Usage: Designed for internal boring and turning finishing, suitable for Mini CNC lathes and similar machines.

- Hardness: HRA 91–93.5

- Accuracy: ±0.005 mm

- Coating: Tailored to your specific application. The smooth, fine surface of the coated carbide ensures excellent surface finish.

- Key Differences from MPR:a. Rear end tilt, whereas MPR features a round shank.b. Different coating options.c. Compatibility with various tool holders.

- Key Differences from MBCR: A smaller tip dip angle of 22° compared to MBCR's 47°.

- Tool Production: Our strong R&D capabilities and advanced equipment enable us to consistently meet your diverse requirements.

As for finished product of MBQR , specific product information as below:

| Brand Name: |

Drow |

| Model Number: |

MBQR Profiling tool |

| Customized support: |

OEM, ODM, OBM. |

| Standard: |

ISO |

| Product type: |

Solid carbide boring tiny tool |

| Material: |

Tungsten Carbide,100% new Material |

| Coating: |

To be defined, with or without coating, Nano coating |

| Hardness: |

HRA 91~93.5 |

| Flute length |

2.0~35.0mm |

| Flute color: |

bronze,matte |

| Precision: |

±0.005mm |

| Shank diameter: |

4.0~7.0mm |

| Shank type |

rear end tilt |

| Tip arc: |

R0.03-R0.20 |

| Mainly Difference to MPR: |

a.Rear end tilt while MPR is round shank.

b.Different coating.

c. suitable for different tool holder. |

| Sample Order: |

Accepted |

| Usage: |

Internal turning and boring for finishing |

| Workpiece Material: |

Steel,Stainless steel,Cast iron and so on |

| Machining type: |

Semi-Finishing/Finishing |

Product Features:

-

No Recalibration Needed: Eliminate the need for tool recalibration, reducing time costs and improving efficiency.

-

Integral Boring Tool Design: The boring tool is integrally formed, and its unique chip flute design minimizes chip buildup, enhancing processing efficiency.

-

Precision Grinding: The entire process utilizes a five-axis machine tool for precision grinding, ensuring high accuracy of the tool tip's r-angle. The cutting edge remains smooth under a microscope at 500x magnification.

-

Internal Cooling Capability: The slotted design on the side of the inclined tail, combined with a center water outlet cutter sleeve, allows for effective internal cooling during processing.

-

Stable Clamping: Solid carbide boring bars are precisely aligned in the adapter using a locating pin, while set screw clamps ensure increased stability for rigid clamping.

-

Easy Tool Replacement: Change tools of the same type easily through the positioning pin, maintaining the same total extension length.

Product Specification:

| Model |

Minimum diameter of machining hole(mm)ΦA |

ΦD |

r |

L1 |

L2 |

F |

S |

JS25 |

AL25 |

| MBQR0406L02R003-D-(C) |

0.6 |

4 |

0.03 |

28 |

2 |

0.55 |

0.06 |

● |

● |

| MBQR0408L025R003-D-(C) |

0.8 |

4 |

0.03 |

28 |

2.5 |

0.75 |

0.08 |

● |

● |

| MBQR0410L04R005-D-(C) |

1.0 |

4 |

0.05 |

29 |

4 |

0.9 |

0.15 |

● |

● |

| MBQR0410L06R005-D-(C) |

1.0 |

4 |

0.05 |

31 |

6 |

0.9 |

0.15 |

● |

● |

| MBQR0412L04R005-D-(C) |

1.2 |

4 |

0.05 |

29 |

4 |

1.1 |

0.15 |

● |

● |

| MBQR0412L06R005-D-(C) |

1.2 |

4 |

0.05 |

31 |

6 |

1.1 |

0.15 |

● |

● |

| MBQR0415L05R005-D-(C) |

1.5 |

4 |

0.05 |

30 |

5 |

1.4 |

0.20 |

● |

● |

| MBQR0415L05R010-D-(C) |

1.5 |

4 |

0.10 |

30 |

5 |

1.4 |

0.20 |

● |

● |

| MBQR0415L08R005-D-(C) |

1. 5 |

4 |

0.05 |

33 |

8 |

1. 4 |

0.20 |

● |

● |

| MBQR0415L08R010-D-(C) |

1.5 |

4 |

0.10 |

33 |

8 |

1.4 |

0.20 |

● |

● |

| MBQR0418L05R005-D-(C) |

1.8 |

4 |

0.05 |

30 |

5 |

1.7 |

0.20 |

● |

● |

| MBQR0418L05R010-D-(C) |

1.8 |

4 |

0.10 |

30 |

5 |

1.7 |

0.20 |

● |

● |

| MBQR0418L09R005-D-(C) |

1.8 |

4 |

0.05 |

34 |

9 |

1.7 |

0.20 |

● |

● |

| MBQR0418L09R010-D-(C) |

1.8 |

4 |

0.10 |

34 |

9 |

1.7 |

0.20 |

● |

● |

| MBQR0421L06R005-D-(C) |

2.1 |

4 |

0.05 |

31 |

6 |

1.85 |

0.25 |

● |

● |

| MBQR0421L06R010-D-(C) |

2.1 |

4 |

0.10 |

31 |

6 |

1.85 |

0.25 |

● |

● |

| MBQR0421L10R005-D-(C) |

2.1 |

4 |

0.05 |

35 |

10 |

1.85 |

0.25 |

● |

● |

| MBQR0421L10R010-D-(C) |

2.1 |

4 |

0.10 |

35 |

10 |

1.85 |

0.25 |

● |

● |

| MBQR0426L08R005-D-(C) |

2.6 |

4 |

0.05 |

33 |

8 |

2.35 |

0.30 |

● |

● |

| MBQR0426L08R010-D-(C) |

2.6 |

4 |

0.10 |

33 |

8 |

2.35 |

0.30 |

● |

● |

| MBQR0426L08R015-D-(C) |

2.6 |

4 |

0.15 |

33 |

8 |

2.35 |

0.30 |

● |

● |

| MBQR0426L12R005-D-(C) |

2.6 |

4 |

0.05 |

37 |

12 |

2.35 |

0.30 |

● |

● |

| MBQR0426L12R010-D-(C) |

2.6 |

4 |

0.10 |

37 |

12 |

2.35 |

0.30 |

● |

● |

| MBQR0426L12R015-D-(C) |

2.6 |

4 |

0.15 |

37 |

12 |

2.35 |

0.30 |

● |

● |

| MBQR0431L10R005-D-(C) |

3.1 |

4 |

0.05 |

35 |

10 |

2.8 |

0.50 |

● |

● |

| MBQR0431L10R010-D-(C) |

3.1 |

4 |

0.10 |

35 |

10 |

2.8 |

0.50 |

● |

● |

MBQR0431L10R015-D-(C)

|

3.1 |

4 |

0.15 |

35 |

10 |

2.8 |

0.50 |

● |

● |

| MBQR0431L15R005-D-(C) |

3.1 |

4 |

0.05 |

40 |

15 |

2.8 |

0.50 |

● |

● |

| MBQR0431L15R010-D-(C) |

3.1 |

4 |

0.10 |

40 |

15 |

2.8 |

0.50 |

● |

● |

| MBQR0431L15R015-D-(C) |

3.1 |

4 |

0.15 |

40 |

15 |

2.8 |

0.50 |

● |

● |

| MBQR0441L12R005-D-(C) |

4.1 |

4 |

0.05 |

37 |

12 |

3.8 |

0.60 |

● |

● |

| MBQR0441L12R010-D-(C) |

4.1 |

4 |

0.10 |

37 |

12 |

3.8 |

0.60 |

● |

● |

| MBQR0441L12R020-D-(C) |

4.1 |

4 |

0.20 |

37 |

12 |

3.8 |

0.60 |

● |

● |

| MBQR0441L16R005-D-(C) |

4.1 |

4 |

0.05 |

41 |

16 |

3.8 |

0.60 |

● |

● |

| MBQR0441L16R010-D-(C) |

4.1 |

4 |

0.10 |

41 |

16 |

3.8 |

0.60 |

● |

● |

| MBQR0441L16R020-D-(C) |

4.1 |

4 |

0.20 |

41 |

16 |

3.8 |

0.60 |

● |

● |

| MBQR0441L20R005-D-(C) |

4.1 |

4 |

0.05 |

45 |

20 |

3.8 |

0.60 |

● |

● |

| MBQR0441L20R010-D-(C) |

4.1 |

4 |

0.10 |

45 |

20 |

3.8 |

0.60 |

● |

● |

| MBQR0441L20R020-D-(C) |

4.1 |

4 |

0.20 |

45 |

20 |

3.8 |

0.60 |

● |

● |

| MBQR0551L15R005-D-(C) |

5.1 |

5 |

0.05 |

40 |

15 |

4.8 |

0.80 |

● |

● |

| MBQR0551L15R010-D-(C) |

5.1 |

5 |

0.10 |

40 |

15 |

4.8 |

0.80 |

● |

● |

| MBQR0551L15R020-D-(C) |

5.1 |

5 |

0.20 |

40 |

15 |

4.8 |

0.80 |

● |

● |

| MBQR0551L20R005-D-(C) |

5.1 |

5 |

0.05 |

45 |

20 |

4.8 |

0.80 |

● |

● |

| MBQR0551L20R010-D-(C) |

5.1 |

5 |

0.10 |

45 |

20 |

4.8 |

0.80 |

● |

● |

| MBQR0551L20R020-D-(C) |

5.1 |

5 |

0.20 |

45 |

20 |

4.8 |

0.80 |

● |

● |

| MBQR0551L25R005-D-(C) |

5.1 |

5 |

0.05 |

50 |

25 |

4.8 |

0.80 |

● |

● |

| MBQR0551L25R010-D-(C) |

5.1 |

5 |

0.10 |

50 |

25 |

4.8 |

0.80 |

● |

● |

| MBQR0551L25R020-D-(C) |

5.1 |

5 |

0.20 |

50 |

25 |

4.8 |

0.80 |

● |

● |

| MBQR0661L15R005-D-(C) |

6. 1 |

6 |

0.05 |

40 |

15 |

5.8 |

1.00 |

● |

● |

| MBQR0661L15R010-D-(C) |

6.1 |

6 |

0.10 |

40 |

15 |

5.8 |

1.00 |

● |

● |

| MBQR0661L15R020-D-(C) |

6. 1 |

6 |

0.20 |

40 |

15 |

5.8 |

1. ,00 |

● |

● |

| MBQR0661L20R005-D-(C) |

6.1 |

6 |

0.05 |

45 |

20 |

5.8 |

1.00 |

● |

● |

| MBQR0661L20R010-D-(C) |

6. 1 |

6 |

0.10 |

45 |

20 |

5.8 |

1.00 |

● |

● |

| MBQR0661L20R020-D-(C) |

6.1 |

6 |

0.20 |

45 |

20 |

5.8 |

1.00 |

● |

● |

| MBQR0661L25R005-D-(C) |

6.1 |

6 |

0.05 |

50 |

25 |

5.8 |

1.00 |

● |

● |

| MBQR0661L25R010-D-(C) |

6.1 |

6 |

0.10 |

50 |

25 |

5.8 |

1.00 |

● |

● |

| MBQR0661L25R020-D-(C) |

6.1 |

6 |

0.20 |

50 |

25 |

5.8 |

1.00 |

● |

● |

| MBQR0661L 30R005-D-(C) |

6.1 |

6 |

0.05 |

55 |

30 |

5.8 |

1.00 |

● |

● |

| MBQR0661L 30R010-D-(C) |

6.1 |

6 |

0.10 |

55 |

30 |

5.8 |

1.00 |

● |

● |

| MBQR0661L30R020-D-(C) |

6.1 |

6 |

0.20 |

55 |

30 |

5.8 |

1.00 |

● |

● |

| MBQR0771L25R010-D-(C) |

7.1 |

7 |

0.10 |

54 |

25 |

6.8 |

1.20 |

● |

● |

| MBQR0771L25R020-D-(C) |

7.1 |

7 |

0.20 |

54 |

25 |

6.8 |

1.20 |

● |

● |

| MBQR0771L35R010-D-(C) |

7.1 |

7 |

0.10 |

64 |

35 |

6.8 |

1.20 |

● |

● |

| MBQR0771L35R020-D-(C) |

7.1 |

7 |

0.20 |

64 |

35 |

6.8 |

1.20 |

● |

● |

| ●:In Stock (C): Support internal coolant customization JS25,AL25: coating code |

Why choose us:

-

Technical Innovation: Complex surfaces and functional structures can be quickly formed while maintaining accuracy.

-

Processing Speed: Short production cycles and fast delivery times ensure that we meet deadlines consistently.

-

Product Quality: High quality is guaranteed, with precision levels reaching up to 0.002-0.001 mm.

-

Confidentiality System: Our triple confidentiality measures protect your information, offering greater assurance during the proofing process.

-

Fully Equipped: We possess excellent processing capabilities, multiple production lines, advanced equipment, and professional supporting facilities.

-

Cost-Effectiveness: Our reasonable design and material selection enable us to offer competitive pricing, helping you secure more favorable rates for products of the same quality.

Quality Inspection

1.Projector detection

2.ZOLLER detection

3.Swis edging

4.German forging difference process detection

5.Edge passivation detection

6.Coreless grinding

FAQ

Q1:Do you produce special cutting tools?

A: Yes,we specialize in customized cutter fabricate and translate the most complex cutting idea into reality, tools manufactured by us are designed and customized for various demanding applications and variety materials!

Q2:Do you accept low volume for sample order? And what’s your MOQ for special tools?

A: Yes, we do. For sample order, MOQ one piece is accepted, and the sample lead time is 2-3 days. It can be negotiated for special requirement.

Q3:If we want to cooperate with you, is it possible to get confidentiality?

A: Sure, all your information including company info, drawings, PO details will be kept confidential, we can signed NDA if you want (non disclosure agreement).

Q4: What is your terms of payment?

A: T/T 30% as deposit, and 70% balance before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q5: What about the package?

A: We use plastic boxes to pack our products, and filled plastic is shockproof and transported in cartons. also It can make as you need and depend on the shapes of the product.

Q6: Who are we?

A:We are based in Guangdong Province, China, start from 2010,sell to Western Europe(10.00%),North America(20.00%),Eastern Europe(20.00%),Southeast Asia(40.00%),Africa(10.00%). There are total about 51-100 people in our factory.

Q7. Can you send products to our Forwarder in China?

A: Yes,if you have Forwarder in China,we will glad to send products to him/her.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!