Product Description:

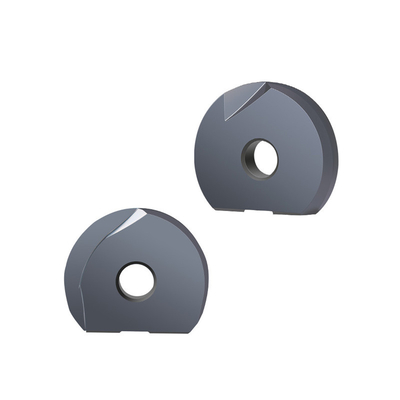

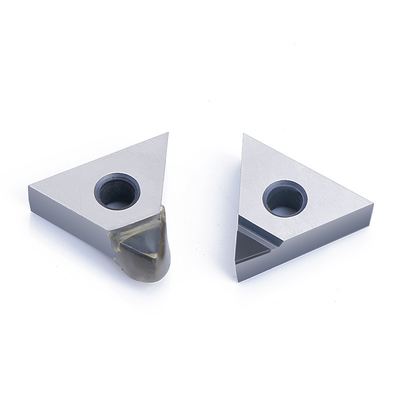

TBP/TBPA is a popular type of CNC carbide back turning & grooving inserts. It is used for various grooving and cutting operations on Lathe and CNC machines, and is available in different shapes and cutting angles to suit different needs.

Production Standard: The production standards of this type of inserts mainly refer to the NTK's TBP/TBPA series. The size details can be customized according to customer requirements.

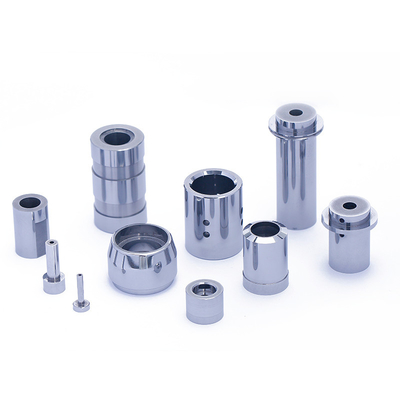

TBP/TBPA/CTP/CTPA: This series, also referred to as the NTK Series of carbide cutting inserts, offers wide-range cutting angles and shape sizes to customers. Its size details can be customized according to customer requirements. This type of insert is suitable for CNC lathes and other CNC machines.

Features:

- Carbide Grooving Inserts

- Tips R Angle: R050/R100/R150/R200 Etc

- Clamp Holder: CTPA_ R/L Etc

- Insert Style: Back Turning

- Standard: Refer To NTK And Kyocera

- Insert Insertion Angle: 90°

- Carbide Back Turning Inserts

- Carbide Back Cutting Inserts

- Carbide Groove Cutter Inserts

Technical Parameters:

| Attribute |

Details |

| Applicable Material(coated) |

Carbon Steel, alloy Steel, mold Steel, other Steel, ductile Iron |

| Number of Cutting Edges |

2 |

| Chipbreaker |

/ |

| Standard |

Refer To NTK And Kyocera |

| Compatible Machine |

CNC Lathes, Centering Machines, Cutter Arranging Machine Skateboard Lathes, Turret Lathes And Other Longitudinal Lathes |

| Insertion Direction |

Right Or Left Hand |

| Clamp Holder |

CTPA_ R/L Etc |

| Dimensions |

W:0.7~3.0mm. θ:0°or 16°. Rε: 0.05~0.1mm. |

| Base Material |

100% Virgin Tungsten Carbide |

| Insert Style |

Back Turning |

Applications:

Drow's Carbide Grooving Inserts are the perfect choice for machining carbon steel, alloy steel, mold steel, other steel, and ductile iron. They feature a two-cutting edge insert style with a 0.7-3.0mm width, 0° or 16° angle, and 0.05-0.1mm radius. Depending on the job, the inserts can be used with either a right or left-hand insertion direction.

These durable and reliable grooving inserts are renowned for their superior performance and long service life, making them a great choice for a variety of machining applications. They are certified to ISO9001 standards and are available in minimum order quantities of 10 pieces.

For convenient and secure ordering, Drow's Carbide Grooving Inserts can be purchased in 10-piece plastic boxes for a price of 4.5 USD per piece. Payment is accepted via 100% T/T before goods are shipped out, with delivery times of 3-7 days and a monthly supply capacity of 100*1000 pcs.

Support and Services:

Carbide Grooving Insert Technical Support and Services

We provide comprehensive technical support and services for carbide grooving inserts.

Installation Guidance

Our team of experts can provide you with one-on-one guidance and advice on how to install your carbide grooving insert correctly. We can also assist you in selecting the right insert for your particular application.

Product Testing

We can provide product testing services to ensure that your carbide grooving insert performs as expected. We can provide test results and analysis reports to help you make the right decision.

Maintenance and Warranty

We offer maintenance and warranty services for our carbide grooving inserts. Our team of experts can provide you with advice and guidance on how to properly maintain your insert and keep it in optimal condition. We also guarantee our products to be free from defects in materials and workmanship.

Packing and Shipping:

Carbide Grooving Inserts are securely packaged in double-layered cardboard boxes with cushioning materials to ensure protection during shipping. The boxes are sealed with tamper-proof adhesive tape.

Shipping is done via a reliable carrier and the delivery time depends on the destination. All packages are tracked to ensure safety and delivery.

FAQ:

- Q: What is the brand name of Carbide Grooving Insert?

- A: The brand name of Carbide Grooving Insert is Drow.

- Q: What is the model number of Carbide Grooving Insert?

- A: The model number of Carbide Grooving Insert is TBP60FR10.

- Q: Where is Carbide Grooving Insert made?

- A: Carbide Grooving Insert is made in China.

- Q: What is the minimum order quantity of Carbide Grooving Insert?

- A: The minimum order quantity of Carbide Grooving Insert is 10pcs.

- Q: What is the price of Carbide Grooving Insert?

- A: The price of Carbide Grooving Insert is 4.5 USD/pcs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!