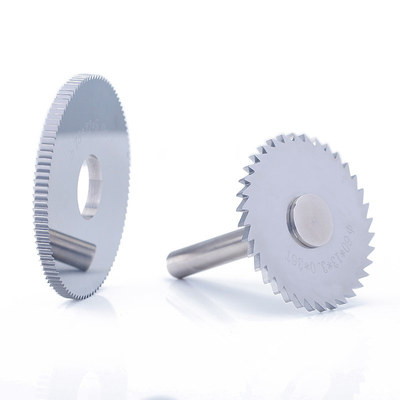

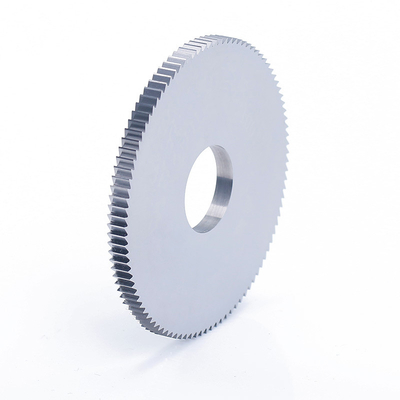

High Wear Resistance Tungsten Carbide Round Saw Blades For Stainless Steel

Application Field:

Tungsten solid carbide saw blades with its high wear resistance are widely used in cutting, grooving and milling, involving in parts manufacturing, mold industry, 3C communication, automotive industry, aerospace, medical machinery etc.

For safety and reliability, solid carbide circular saw blades should only be used on stable and low-vibration machines (preferably milling machines).

As for reasonable teeth number selection,try to use item with more teeth number which lead to higher wear-resistance if working on steel part.

How to Apply Saw Blade by Materials?

| Milled Materials |

Ordinary Steel |

Titanium Alloy |

Brass |

Stainless Steel |

| Vc(m/min) |

70 - 160 |

20 - 60 |

200 - 350 |

80 - 150 |

| Milled Materials |

Chilled Steel |

Aluminium Alloy |

Cast Iron |

|

| Vc(m/min) |

50 - 80 |

200 - 400 |

110 - 130 |

|

Above are tooth milling line speed (Vc, m/min) of solid carbide slitting saw according to sever different milled materials. Once the Vc of diameter of saw blade (D, mm) was confirmed. The rotate speed (n, rev/min) of milling cutter arbor can be calculated

And if cutter speed (St, mm/T) was required, with tooth number of cutter (T). The cutting feed speed (Vf) can be calculated:

Product Details---Saw Blades for Stainless Steel

1.Material: Tungsten Carbide, 100% New Material with high wear resistance and hardness.

2.Usage:Suitable for stainless steel and other hard material etc.

3.Specification:D10~180mm,Thickness0.2~6.0mm,6~280T.

4.Customization: It's available to specialize your order according to your drawings. Kindly provide us

some necessary parameter include Outer diameter, thickness, inner hole diameter, number of teeth, as well as the material you require to process.

Product Features:

1. High-precision mirror treatment for every saw blade

2. High-precision air-avoidance grinding, make cutting fast and smooth, the incision surface is smooth and burr-free

3. Imported machine tool precision grinding

4. Due to the latest tool technology and the highest quality standards, Drow solid carbide circular saw blades achieve greatest cutting speeds.

Product Specification:

Specification example as below shows, other specifications can be supported if you need to customize.

|

Outside Diameter

mm

|

Thickness

mm

|

Inner Diameter

mm

|

Teeth Number |

| 10 |

0.2~4 |

4/5 |

6~24 |

| 12 |

0.2~4 |

4/5/6 |

6~30 |

| 16 |

0.2~4 |

5/6/8 |

6~40 |

| 20 |

0.2~4 |

5/6/8 |

6~45 |

| 22 |

0.2~5 |

5/6/8 |

8~50 |

| 25 |

0.2~5 |

6/8/10 |

10~56 |

| 30 |

0.2~5 |

6/8/10 |

10~60 |

| 32 |

0.2~6 |

6/8/10/12.7 |

10~60 |

| 35 |

0.2~6 |

8/10/12.7 |

10~60 |

| 40 |

0.2~6 |

8/10/12.7 |

10~80 |

| 45 |

0.2~8 |

10/12.7/16 |

10~80 |

| 50 |

0.2~8 |

10/12.7/16 |

10~100 |

| 55 |

0.2~8 |

12.7/16 |

24~120 |

| 60 |

0.2~8 |

12.7/13/16 |

24~120 |

| 70 |

0.3~8 |

16/22/25.4 |

28~120 |

| 75 |

0.5~8 |

16/22/25.4 |

30~120 |

| 80 |

0.5~8 |

22/25.4 |

30~128 |

| 85 |

0.5~8 |

22/25.4 |

30~128 |

| 90 |

0.5~8 |

22/25.4 |

30~160 |

| 95 |

0.5~8 |

22/25.4 |

30~160 |

| 100 |

0.5~8 |

22/25.4/27 |

30~160 |

| 105 |

0.8~8 |

22/25.4/27 |

30~160 |

| 110 |

0.8~8 |

22/25.4/27/32 |

30~180 |

| 115 |

0.8~8 |

22/25.4/27/32 |

30~180 |

| 120 |

1~10 |

22/25.4/27/32 |

30~240 |

| 125 |

1~10 |

22/25.4/27 |

30~240 |

| 130 |

1~10 |

22/25.4/27/32 |

30~240 |

| 150 |

1~10 |

22/25.4/27/32 |

40~240 |

| 160 |

1~10 |

22/25.4/27/32 |

40~240 |

| 180 |

1.5~12 |

25.4/27/32/40 |

60~280 |

Why Choose Us

1.Advanced Technology: Complex surfaces and functional structures can be quickly formed and kept accurate.

2.Short Machining Period: Short production cycle to ensure delivery on time according to the delivery date.

3.Crowned Product: High quality guaranteed.High precision, up to 0.005-0.001mm.

4.Confidentiality System: Triple confidentiality measures to protect customer’s private design. Proofing more assured.

5.Fully Equipment: Excellent processing capacity, multiple production lines, advanced equipment, professional supporting facilities.

6.Cost-effective: Reasonable design and material selection lead us to a competitive price, so that could help supply customers cheaper price of the same level products .

Production Machinery:

| Machine Name |

Brand & Model No. |

Condition |

| Surface Grinding Machine |

Confidential |

Available |

| Grinding Wheel Dressing Machine |

Confidential |

Available |

| Grinding Wheel Pre Setter |

Confidential |

Available |

| Cylindrical Grinding Machine Internal |

Confidential |

Available |

| Centerless Grinding Machine |

Confidential |

Available |

| 5-Axis CNC Grinding Machine |

Confidential |

Available |

| Edge Preparing Machine |

Confidential |

Available |

| Cylindrical Grinding Machine |

Confidential |

Available |

| Laser Marking Machine |

Confidential |

Available |

| Sand Blasting Machine |

Confidential |

Available |

| Cutting Off Machine |

Confidential |

Available |

Quality Control Machine:

| Machine Name |

Brand & Model No. |

Condition |

| Runout Tester |

Confidential |

Available |

| Balance Tester |

Confidential |

Available |

| Projector |

Confidential |

Available |

| Image Measuring Machine |

Confidential |

Available |

| Height Hauge |

Confidential |

Available |

| Tooling Inspection and Inspection Machine |

Confidential |

Available |

| Micrometer |

Confidential |

Available |

| Electronic Microscope |

Confidential |

Available |

FAQ

Q1:Do you produce special cutting tools?

A: Yes,we specialize in customized cutter fabricate and translate the most complex cutting idea into reality, tools manufactured by us are designed and customized for various demanding applications and variety materials!

Q2:Do you accept low volume for sample order? And what’s your MOQ for special tools?

A: Yes, we do. For sample order, MOQ one piece is accepted, and the sample lead time is 2-3 days. It can be negotiated for special requirement.

Q3:If we want to cooperate with you, is it possible to get confidentiality?

A: Sure, all your information including company info, drawings, PO details will be kept confidential, we can signed NDA if you want (non disclosure agreement).

Q4: What is your terms of payment?

A: T/T 30% as deposit, and 70% balance before delivery. We'll show you the photos of the products and packages before you pay the balance.

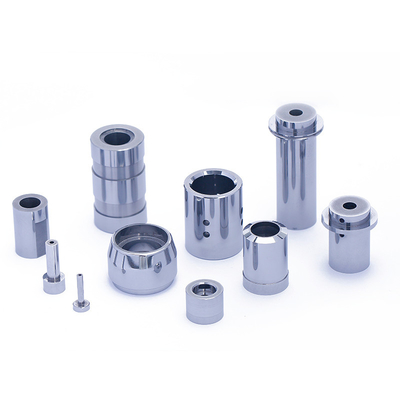

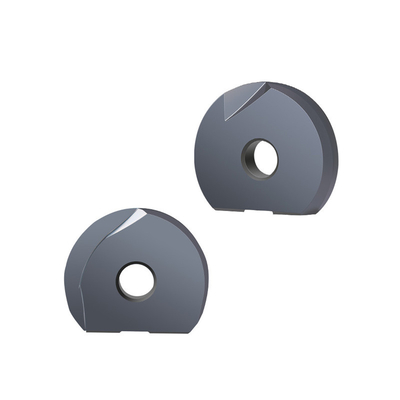

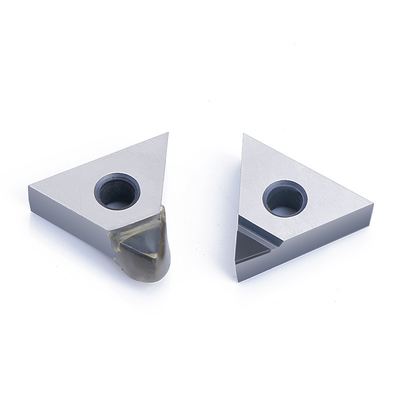

Q5: what can you buy from us?

A: Carbide insert,carbide end mill,carbide drill,carbide boring,cutting tools&customized carbide precision molds.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!