MGSR High Efficiency Internal Grooving & Boring Tool for Mini CNC Turning Lathe

Drow_Carbide_Boring_Tools_EN.pdf

Drow_Carbide_Boring_Tools_MD_EN.pdf

Application Field:

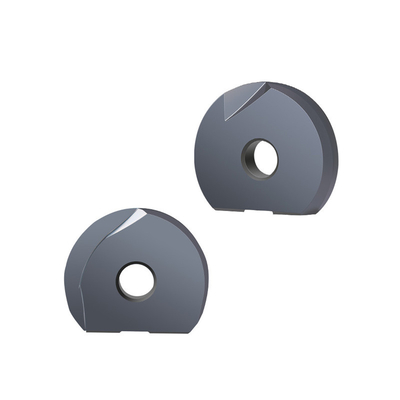

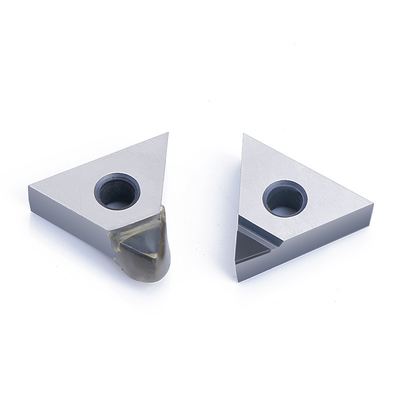

The MGSR is a kind of internal boring and slotting cutter, widely used in the metal internal gooving of mini CNC turning machine tools or lathe.Different to round shank MGR, MGSR is rear end tilt and suitable for locking precision tool holders. Besides, with different advanced nano coating on ultrafine carbide, this tool achieves high smooth machining surface and wear resistance.

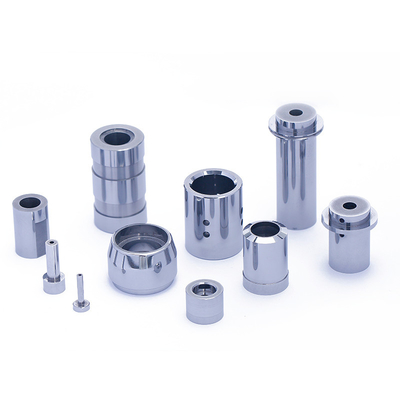

Product Details--- MGSR Internal Grooving Tool

- Tool Material : 100% virgin tungsten carbide.

- Usage: For Inner hole reverse boring cutter.

- Hardness: HRA91~93.5

- Accuracy: ±0.005mm

- Coating :To be defined per your application. Smooth fine surface of coated carbide provides good surface finish.

- Mainly Difference to MGR: a.Rear end tilt while MGR is round shank. b. Different coating. c. suitable for different tool holder.

- Tool production : Our strong R&D power and advanced equipment can always support us to meet your various requirement.

Summary product information as below:

| Brand Name: |

Drow |

| Model Number: |

MGSR internal grooving tool |

| Customized support: |

OEM, ODM. |

| Standard: |

ISO |

| Product type: |

Solid carbide boring tiny tool |

| Material: |

Tungsten Carbide,100% new Material |

| Coating: |

To be defined per your different demands and application |

| Hardness: |

HRA 91~93.5 |

| Band width: |

0.50~2.00mm |

| Flute length: |

10.0~25.0mm |

| Flute color: |

bronze,matte |

| Precision: |

±0.005mm |

| Shank diameter: |

4.0~7.0mm |

| Shank type: |

rear end tilt |

| Tip arc: |

R0.05-R0.10(±0.01) |

| Mainly Difference to MGR: |

a.Rear end tilt while MGR is round shank.

b.Different coating.

c. Suitable for different tool holder. |

| Sample Order: |

Accepted |

| Usage: |

Suitable for metal inner hole grooving machining |

| Workpiece Material: |

Steel,Stainless steel,Cast iron and so on |

| Machining type: |

Semi-Finishing/Finishing |

Product Features:

1.No need to re-calibrate tools Reduce time cost Improve efficiency.

2.The boring tool is integrally formed. Besides,unique chip flute design reduces chip buildup Improve processing efficiency.

3.The whole process adopts five-axis machine tool for precision grinding.High precision of the r-angle of the tool tip,and the cutting edge is smooth under the 500 times microscope.

4.Slotted design on the side of the inclined position at the tail, with the center water outlet cutter sleeve,it can realize internal cooling processing.

5.Solid carbide boring bars are precisely positioned into the adaptor by a locating pin.Set screw clamp bars ensure increased stability for rigid clamping.

6.Change the tool with the same type through the positioning pin,and the total extension length is the same.

Product Specification:

| Model |

Minimum diameter of machining hole(mm)ΦA |

ΦD |

r±0.01 |

L1 |

L2 |

F |

S |

W |

JS25 |

AL25 |

| MGSR0431L10W050-D-(C) |

3.1 |

4 |

0.05 |

35 |

10 |

2.8 |

0.80 |

0.50 |

● |

● |

| MGSR0431L10W075-D-(C) |

3.1 |

4 |

0.05 |

35 |

10 |

2.8 |

0.80 |

0.75 |

● |

● |

| MGSR0431L10W100-D-(C) |

3.1 |

4 |

0.05 |

35 |

10 |

2.8 |

0.80 |

1.00 |

● |

● |

| MGSR0441L12W050-D-(C) |

4.1 |

4 |

0.05 |

37 |

12 |

3.8 |

1.00 |

0.50 |

● |

● |

| MGSR0441L12W075-D-(C) |

4.1 |

4 |

0.05 |

37 |

12 |

3.8 |

1.00 |

0.75 |

● |

● |

| MGSR0441L12W100-D-(C) |

4.1 |

4 |

0.05 |

37 |

12 |

3.8 |

1.00 |

1.00 |

● |

● |

| MGSR0441L12W150-D-(C) |

4.1 |

4 |

0.05 |

37 |

12 |

3.8 |

1.00 |

1.50 |

● |

● |

| MGSR0551L15W100-D-(C) |

5.1 |

5 |

0.10 |

40 |

15 |

4.8 |

1.50 |

1.00 |

● |

● |

| MGSR0551L15W150-D-(C) |

5.1 |

5 |

0.10 |

40 |

15 |

4.8 |

1.50 |

1.50 |

● |

● |

| MGSR0551L15W200-D-(C) |

5.1 |

5 |

0.10 |

40 |

15 |

4.8 |

1.50 |

2.00 |

● |

● |

| MGSR0661L20W100-D-(C) |

6.1 |

6 |

0.10 |

45 |

20 |

5.8 |

2.00 |

1.00 |

● |

● |

| MGSR0661L20W150-D-(C) |

6.1 |

6 |

0.10 |

45 |

20 |

5.8 |

2.00 |

1. 50 |

● |

● |

| MGSR0661L20W200-D-(C) |

6.1 |

6 |

0.10 |

45 |

20 |

5.8 |

2.00 |

2.00 |

● |

● |

| MGSR0771L25W100-D-(C) |

7.1 |

7 |

0.10 |

54 |

25 |

6.8 |

2.00 |

1.00 |

● |

● |

| MGSR0771L25W150-D-(C) |

7.1 |

7 |

0.10 |

54 |

25 |

6.8 |

2.00 |

1. 50 |

● |

● |

| MGSR0771L25W200-D-(C) |

7.1 |

7 |

0.10 |

54 |

25 |

6.8 |

2.50 |

2.00 |

● |

● |

| ●:In Stock (C): Support internal coolant customization JS25,AL25: coating code |

Why choose us:

1.Technical innovation: complex surfaces and functional structures can be quickly formed and kept accurate.

2.Processing speed: short production cycle, fast delivery time, to ensure delivery on time according to the delivery date.

3.Product quality: high quality guaranteed,high precision, up to 0.002-0.001mm.

4.Confidentiality system: triple confidentiality measures to protect, proofing more assured.

5.Fully equipped: excellent processing capacity, multiple production lines, advanced equipment, professional supporting facilities.

6.Cost-effective: reasonable design and material selection lead us to a competitive price, so that could help provide you more favorable price of the same level products .

Quality Inspection

1.Projector detection

2.ZOLLER detection

3.Swis edging

4.German forging difference process detection

5.Edge passivation detection

6.Coreless grinding

FAQ

Q1:Do you produce special cutting tools?

A: Yes,we specialize in customized cutter fabricate and translate the most complex cutting idea into reality, tools manufactured by us are designed and customized for various demanding applications and variety materials!

Q2:Do you accept low volume for sample order? And what’s your MOQ for special tools?

A: Yes, we do. For sample order, MOQ one piece is accepted, and the sample lead time is 2-3 days. It can be negotiated for special requirement.

Q3:If we want to cooperate with you, is it possible to get confidentiality?

A: Sure, all your information including company info, drawings, PO details will be kept confidential, we can signed NDA if you want (non disclosure agreement).

Q4: What is your terms of payment?

A: T/T 30% as deposit, and 70% balance before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q5: what can you buy from us?

A: Carbide insert,carbide end mill,carbide drill,carbide boring,cutting tools&customized carbide precision molds.

Q6: How do you keep long-term and good relationship with our business?

A:1. Consistent quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend. We sincerely do business and make friends with them, no matter where they come from.

Q7. Can you send products to our Forwarder in China?

A: Yes,if you have Forwarder in China,we will glad to send products to him/her.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!