What is carbide boring tool? How to choose a suitable carbide boring tools

Drow Carbide Precision Ltd. Releases Industry Guide: Demystifying Carbide Boring Tool Selection

February 20, 2025** - As manufacturing intelligence accelerates, Drow Carbide Precision Ltd. today officially released the "High-Precision Cutting Tool Selection Whitepaper," providing in-depth analysis of carbide boring tools' technical characteristics and selection strategies for machining enterprises.

### Technical Analysis of Carbide Boring Tools

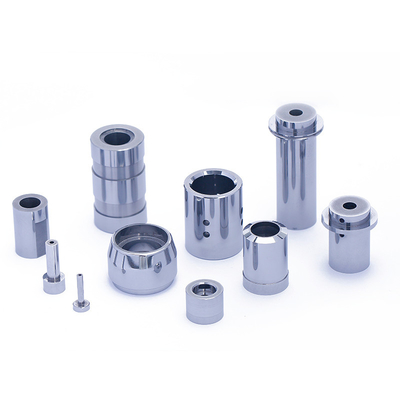

Carbide boring tools, manufactured using tungsten carbide-based materials, demonstrate outstanding advantages:

- **Exceptional Wear Resistance**: Hardness up to HRA92-94, 5-8× longer service life than HSS tools

- **High Thermal Stability**: Withstands 800-1000°C for high-speed cutting

- **Precision Machining**: Achieves IT6-IT7 tolerance grades with surface roughness Ra0.4-0.8μm

### Five-Dimensional Selection Methodology

Drow Carbide's CTO recommends considering five critical dimensions:

1. **Material Compatibility**

CVD-coated tools for cast iron, PVD nano-coated for stainless steel

2. **Operation-specific Tool Selection**

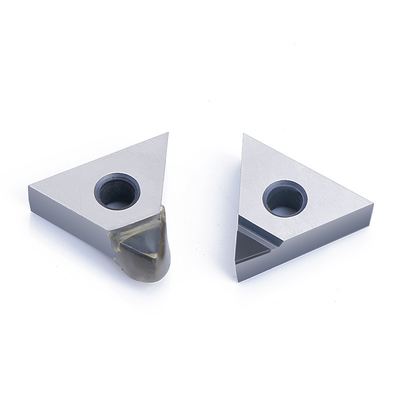

- **Face Grooving**:

▸ Suitable for engine block oil grooves (width 2-8mm)

▸ Recommend TPGX insert with 85° approach angle

▸ Cutting speed [v_c = 120-180m/min] for aluminum alloys

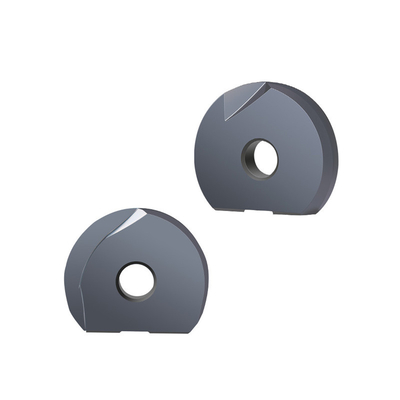

- **Profiling Boring**:

▸ Complex contour machining in aerospace components

▸ Use variable geometry boring heads with ±0.01mm repeatability

▸ Chip breaker geometry: [λ = 15°-20°] for steel machining

- **Internal Threading**:

▸ Metric/UN thread machining in hydraulic manifolds

▸ 60° V-type inserts with TiAlN coating

▸ Feed rate [f = pitch times 0.7] for ISO metric threads

- **Reverse Boring**:

▸ Back-side machining of turbine casings

▸ Reverse-angle cutters with 45° lead angle

▸ Rigidity requirement: [k geq 200N/μm] at overhang 5xD

- **Internal Boring**:

▸ General precision hole finishing

▸ Modular boring systems with 0.001mm adjustment resolution

▸ Depth-diameter ratio [L/D leq 4] without auxiliary support

3. **Geometric Parameters**

Rake angle γ selection based on material hardness:

[

γ =

begin{cases}

8°-10° & text{Cast Iron}

12°-15° & text{Aluminum Alloy}

end{cases}

]

4. **Toolholder Systems**

HSK for high-speed applications (≤18,000rpm) vs CAPTO for heavy cutting

5. **Supplier Capabilities**

Evaluate tool presetting services, on-site support, and custom solution responsiveness

**About Drow Carbide Precision Ltd.**

As a national high-tech enterprise, we hold 12 carbide tool patents and operate German-made 5-axis tool grinding clusters, offering 72-hour rapid customization. Download the full whitepaper at www.drowcn.cn.

*Media Contact:

Sales manager Mr Chen | WhatsApp/Wechat: +8618975739143 | Zalo/Telegram: +8615622340665

Email: csc@drowcn.cn*

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!