5 Key Factors to Ensure Precision in Stamping Die Manufacturing

Achieving micron-level precision in stamping dies requires strict control over five critical parameters:

1. Material Selection

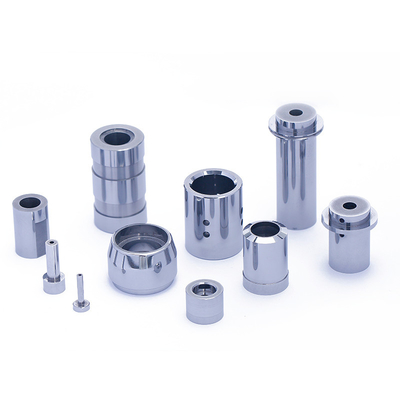

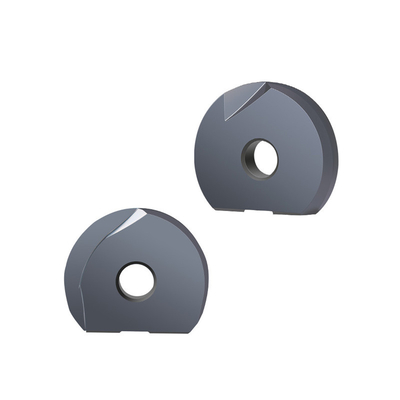

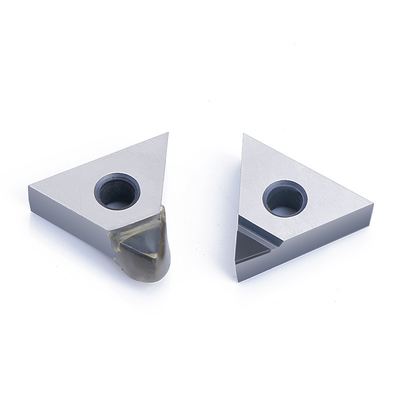

- Tungsten Carbide (ISO K10-K40):

With hardness up to HRA 92.5, it’s ideal for high-wear applications like electronic connector pin stamping.

- Powdered High-Speed Steel (ASP® 30):

Suitable for complex geometries, offering HRC 64-66 hardness post-heat treatment.

2. Surface Finish Optimization

- Post-EDM Polishing Process:

- Rough Polishing: #400 diamond grinding wheels (Ra 0.4μm → 0.2μm).

- Fine Polishing: Chemical-mechanical polishing (CMP) achieves Ra <0.05μm.

- Drow PG Series Dies:

Mirror polishing technology ensures consistent stamped part roughness below Ra 0.1μm.

3. Thermal Management

- Conformal Cooling Channels:

Maintain die temperature within ±2°C to minimize thermal deformation.

- Case Data:

A customer producing smartphone metal casings increased die lifespan from 500k to 820k cycles.

4. Tolerance Control

- Micro-Hole Machining:

Achieves ±0.002mm bore tolerance using 0.1mm-diameter micro-EDM electrodes.

- Drow Kinyet Sub-Brand:

PG Punch Pins guarantee straightness of 0.001mm/100mm.

5. Maintenance Protocols

- Daily Checks:

Clean residual oil with pH-neutral solvents.

- Monthly Calibration:

Verify flatness via laser interferometry (threshold: ≤0.003mm).

Internal Links:

- Case Study: `/en/stamping-die-case-study`

- Whitepaper: `/en/surface-finish-standards`

- Product Catalog: `/en/tungsten-carbide-dies`

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!